Signaling

Summary: Signaling is vital for realistic operations, however it's not vital for model railroading. There are many ways to add signaling to your layout and can get quite complex. There are books on signaling, so it's recommended that you research how you want your signaling to be. At this time, this article does not go into all the aspects of signaling, but it does give you examples of how to connect various DCC hardware to get signaling working.

|

See the Video. |

Considerations When Planning a Signaling System

Before buying any signaling equipment, there are some important things to consider before approaching a signaling system for a layout.

First, what type of signaling system do you want to emulate. Also, to what degree of actual prototypical operation do you want to achieve.

Second, what type of logic control are you going to implement which sets the signals. For example, the Digitrax SE8C can control up to 32 signal heads but has absolutely no logic for which to control them; thus, it relies on some sort of external logic (computer or separate logic board) to set the signals.

Third, you will need to get block detection working on your DCC layout.

Generally, a signaling system needs to know the current route (turnout routing) and availability of track ahead (block occupancy). You may also want to know the power status of the route ahead (power management). This information can be used to affect the aspect (signal state) for a given signaling block. Your logic board or software program may or may not be able to accommodate all these type inputs. Also, these may or may not be on your list of requirements for your signaling system.

Prototype Signaling

Timetable Operations

The simplest form of operation, at least in terms of equipment, is to run the system according to a timetable. Every train crew understands and adheres to a fixed schedule. Trains may only run on each track section at a scheduled time, during which they have 'possession' and no other train may use the same section.

When trains run in opposite directions on a single-track railroad, meeting points ("meets") are scheduled, at which each train must wait for the other at a passing place. Neither train is permitted to move before the other has arrived. In the US the display of two green flags (green lights at night) is an indication that another train is following the first and the waiting train must wait for the next train to pass. In addition, the train carrying the flags gives eight blasts on the whistle as it approaches. The waiting train must return eight blasts before the flag carrying train may proceed.

The timetable system has several disadvantages. First, there is no positive confirmation that the track ahead is clear, only that it is scheduled to be clear. The system does not allow for engine failures and other such problems, but the timetable is set up so that there should be sufficient time between trains for the crew of a failed or delayed train to walk far enough to set warning flags, flares, and detonators or torpedoes (UK and US terminology, respectively) to alert any other train crew. A second problem is the system's inflexibility. Trains cannot be added, delayed, or rescheduled without advance notice.

A third problem is a corollary of the second: the system is inefficient. To provide flexibility, the timetable must give trains a broad allocation of time to allow for delays, so the line is not in the possession of each train for longer than is otherwise necessary.

Nonetheless, this system permits operation on a vast scale, with no requirements for any kind of communication that travels faster than a train. Timetable operation was the normal mode of operation in North America in the early days of the railroad.

Timetable and Train Order

With the advent of the telegraph in 1841, a more sophisticated system became possible because this provided a means whereby messages could be transmitted ahead of the trains. The telegraph allows the dissemination of any timetable changes, known as train orders. These allow the cancellation, rescheduling and addition of train services.

North American practice meant that train crews generally received their orders at the next station at which they stopped, or were sometimes handed up to a locomotive 'on the run' via a long staff. Train orders allowed dispatchers to set up meets at sidings, force a train to wait in a siding for a priority train to pass, and to maintain at least one block spacing between trains going the same direction.

Timetable and train order operation was commonly used on American railroads until the 1960s, including some quite large operations such as the Wabash Railroad and the Nickel Plate Road. Train order traffic control was used in Canada until the late 1980s on the Algoma Central Railway and some spurs of the Canadian Pacific Railway. Timetable and train order was not used widely outside North America, and has been phased out in favor of radio dispatch on many light-traffic lines and electronic signals on high-traffic lines. More details of North American operating methods are given below.

A similar method, known as 'Telegraph and Crossing Order' was used on some busy single lines in the UK during the 19th century. However, a series of head-on collisions resulted from authority to proceed being wrongly given or misunderstood by the train crew - the worst of which was the collision between Norwich and Brundall, Norfolk, in 1874. As a result, the system was phased out in favour of token systems. This eliminated the danger of ambiguous or conflicting instructions being given because token systems rely on objects to give authority, rather than verbal or written instructions; whereas it is very difficult to completely prevent conflicting orders being given, it is relatively simple to prevent conflicting tokens being handed out.

Types of Signaling

Trains cannot collide if they are not permitted to occupy the same section of track at the same time, so railway lines are divided into sections known as blocks. In normal circumstances, only one train is permitted in each block at a time. This principle forms the basis of most railway safety systems. Blocks can either be fixed (block limits are fixed along the line) or moving blocks (ends of blocks defined relative to moving trains).

Permissive and Absolute Blocks

Under a permissive block system, trains are permitted to pass signals indicating the track ahead is occupied, but only at such a speed that they can stop safely should an obstacle come into view. This allows improved efficiency in some situations and is mostly used in the USA. In most countries it is restricted to freight trains only, and it may be restricted depending on the level of visibility.

Under a permissive block system, trains are permitted to pass signals indicating the line ahead is occupied, but only at such a speed that they can stop safely should an obstacle come into view. This allows improved efficiency in some situations and is mostly used in the USA. In most countries it is restricted to freight trains only, and it may be restricted depending on the level of visibility.

Permissive block working may also be used in an emergency, either when a driver is unable to contact a signalman after being held at a danger signal for a specific time, although this is only permitted when the signal does not protect any conflicting moves, and also when the signalman is unable to contact the next signal box to make sure the previous train has passed, for example if the telegraph wires are down. In these cases, trains must proceed at very low speed (typically 32 km/h (20 mph) or less) so that they are able to stop short of any obstruction. In most cases, this is not allowed during times of poor visibility (e.g., fog or falling snow).

Even with an absolute block system, multiple trains may enter a block with authorization. This may be necessary in order to split or join trains together, or to rescue failed trains. In giving authorization, the signalman also ensures that the driver knows precisely what to expect ahead. The driver must operate the train in a safe manner taking this information into account. Generally, the signal remains at danger, and the driver is given verbal authority, usually by a yellow flag, to pass a signal at danger, and the presence of the train in front is explained. Where trains regularly enter occupied blocks, such as stations where coupling takes place, a subsidiary signal, sometimes known as a "calling on" signal, is provided for these movements, otherwise they are accomplished through train orders.

Automatic Block Signals

Under automatic block signalling, signals indicate whether or not a train may enter a block based on automatic train detection indicating whether a block is clear. The signals may also be controlled by a signalman, so that they only provide a proceed indication if the signalman sets the signal accordingly and the block is clear.

Fixed Block

Most blocks are fixed, i.e. they include the section of track between two fixed points. On timetable, train order, and token-based systems, blocks usually start and end at selected stations. On signalling-based systems, blocks start and end at signals.

The lengths of blocks are designed to allow trains to operate as frequently as necessary. A lightly used line might have blocks many kilometres long, but a busy commuter line might have blocks a few hundred metres long.

A train is not permitted to enter a block until a signal indicates that the train may proceed, a dispatcher or signalman instructs the driver accordingly, or the driver takes possession of the appropriate token. In most cases, a train cannot enter the block until not only the block itself is clear of trains, but there is also an empty section beyond the end of the block for at least the distance required to stop the train. In signalling-based systems with closely spaced signals, this overlap could be as far as the signal following the one at the end of the section, effectively enforcing a space between trains of two blocks.

When calculating the size of the blocks, and therefore the spacing between the signals, the following have to be taken into account:

- Line speed (the maximum permitted speed over the line-section)

- Train speed (the maximum speed of different types of traffic)

- Gradient (to compensate for longer or shorter braking distances)

- The braking characteristics of trains (different types of train, e.g., freight, High-Speed passenger, have different inertial figures)

- Sighting (how far ahead a driver can see a signal)

- Reaction time (of the driver)

Historically, some lines operated so that certain large or high-speed trains were signalled under different rules and only given the right of way if two blocks in front of the train were clear.

Moving Block

One disadvantage of fixed blocks is that if faster trains are allowed to run, they require longer stopping distances, necessitating longer blocks, while decreasing the line's capacity. Fixed blocks must be sized for the worst-case stopping distance, regardless of the actual speed of the trains. Under a moving block system, computers calculate a "safe zone" around each moving train that no other train is allowed to enter. The system depends on knowledge of the precise location and speed and direction of each train, which is determined by a combination of several sensors: active and passive markers along the track, and train borne speedometers; (GPS systems cannot be relied upon because they do not work in tunnels). With a moving block setup, lineside signals are unnecessary, and instructions are passed directly to the trains. This has the advantage of increasing track capacity by allowing trains to run closer together while maintaining the required safety margins.

CTC

Centralized traffic control (CTC) is a form of railway signalling that originated in North America. CTC consolidates train routing decisions that were previously carried out by local signal operators or the train crews themselves. The system consists of a centralized train dispatcher's office that controls railroad interlockings and traffic flows in portions of the rail system designated as CTC territory.

Prototype Signals

Prototype railroads use a number of physical signals erected along the line. These are used to communicate with the engineer various instructions related to the line ahead.

Mechanical Signals

Older forms of signal displayed their different aspects by their physical position. The earliest types comprised a board that was either turned face-on and fully visible to the driver, or rotated so as to be practically invisible. While this type of signal is still in use in some countries (e.g., France and Germany), by far the most common form of mechanical signal worldwide is the semaphore signal. This comprises a pivoted arm or blade that can be inclined at different angles. A horizontal arm is the most restrictive indication (for 'danger', 'caution', 'stop and proceed' or 'stop and stay' depending on the type of signal).

To enable trains to run at night, one or more lights are usually provided at each signal. Typically, this comprises a permanently lit oil lamp with movable coloured spectacles in front that alter the colour of the light. The driver therefore had to learn one set of indications for daytime viewing and another for nighttime viewing.

Whilst it is normal to associate the presentation of a green light with a safe condition, this was not historically the case. In the very early days of railway signalling, the first coloured lights (associated with the turned signals above) presented a white light for 'clear' and a red light for 'danger'. Green was originally used to indicate 'caution' but fell out of use when the time interval system was discontinued. A green light subsequently replaced white for 'clear', to address concerns that a broken red lens could be taken by a driver as a false 'clear' indication. It was not until scientists at Corning Glassworks perfected a shade of yellow without any tinges of green or red that yellow became the accepted colour for 'caution'.

Mechanical signals are usually remotely operated by wire from a lever in a signal box, but electrical or hydraulic operation is normally used for signals that are located too distant for manual operation.

Coloured Light Signals

On most modern railways, colour light signals have largely replaced mechanical ones. Colour light signals have the advantage of displaying the same aspects by night as by day, and require less maintenance than mechanical signals.

Although signals vary widely between countries, and even between railways within a given country, a typical system of aspects would be:

- Green: Proceed at line speed. Expect to find next signal displaying green or yellow.

- Yellow: Prepare to find next signal displaying red.

- Red: Stop.

On some railways, colour light signals display the same set of aspects as shown by the lights on mechanical signals during darkness.

Signal Control Hardware

There are various types of DCC hardware that can be used to control your signals.

For a list of available signal decoders see the Signal Decoder page.

Digitrax SE8C

- Main article: SE8C

The SE8C is a powerful plug and play signal decoder. It makes the addition of prototypical signalling to your layout easy. Can drive up to 32 signals. Despite not having any logic on board, this is still a very powerful product.

Features

The SE8C has the ability to control up to 32 signal heads (four on each of the eight ribbon cables), eight turnouts (more, if you wire slow motion switch machines in series or parallel), and handle up to eight sensor inputs.

Because the SE8C can also control 8 slow motion switches, this might save you some money in not needing additional stationary decoders to control the actual switches.

The biggest drawback on the SE8C is that there is no logic. You can control it manually with the proper throttle but it is an extreme pain. Another option is a logic board. If you are running automation software, the best choice is to use a computer and software. It is really super to have all the signals operate correctly and automatically as the train travel across all SE8C boards.

Considering all that the SE8C is capable of, there is a lot of bang for the buck with this board. For the cost of enough stationary decoders to control eight turnouts (crossovers), you can purchase the SE8C, and basically get the signalling thrown in for free.

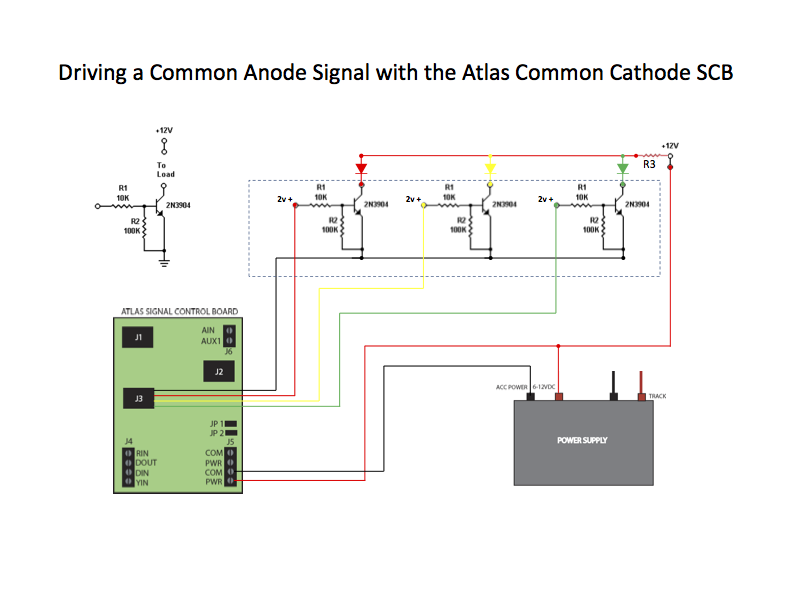

Using Common Cathode Drivers with Common Anode Signals

If you have a circuit designed to drive common cathode signals, but bought one that is common anode, you need to make another simple circuit to make it work.

Further Reading

- Printed Materials on Signaling

- Making Resistor Wheelsets, RR-Cirkits

External Websites

Sections relating to prototype signalling were taken from the Wikipedia

- https://en.wikipedia.org/wiki/Railway_signalling

- https://en.wikipedia.org/wiki/Interlocking

- https://en.wikipedia.org/wiki/Automatic_block_signaling

- https://en.wikipedia.org/wiki/Train_order_operation

- https://en.wikipedia.org/wiki/Track_circuit

- https://en.wikipedia.org/wiki/Railway_signal

- RailRoadSignals.Net

- North American Signaling by Carsten S. Lundsten

- About Centralized Traffic Control

Books

- Solomon, Brian (2010). Railroad Signalling Voyageur Press. pp. 30–31. ISBN 0-7603-3881-7.

- Solomon, Brian (2015). Railway Depots, Stations & Terminals]. Minneapolis: Voyageur Press. p. 62.

- Solomon, Brian (2003). Railroad Signaling. Minneapolis: Voyageur Press. p. 31. train order signal.

Videos

How to Read Canadian Signals

Trackwork

The next installment of the Railroad 101 series! In this video, we talk about the important parts of railroad track, how they work together, how they are measured, and how track itself is measured, classified, and it's types. This is an important fundamental level course as a primer for upcoming signals and interlockings videos :)

Signal Design

In this installment of the Railroad 101 series, we look at Railroad Signal Design! We go over 10 different levels of understanding of signals, focusing on the fun behind-the-scenes stuff that most folks don't get to hear about, as my current job is being a signal design engineer.