Converting to DCC

Summary: This article describes the steps for converting your layout from Analog (Direct Current) to Digital Command Control. Remember, converting from analog to DCC can be costly and time consuming - but it is very rewarding once you have done so. Upgrading locomotives with Multifunction Decoders can be completed at your own pace. The track wiring needs to be done all at once since you cannot run Analog and Digital Command Control power at the same time.

| Tutorial Topics |

|

| DCC Core Topics |

|

The Basics of Converting to Digital Command Control

This article assumes that:

- You have read the DCC Tutorial and optionally the Introduction to DCC so that you understand the basic principles of DCC;

- That you have selected a DCC system, which you may or may not have purchased it yet; and

- You have read the Wiring Your Layout article.

Overview

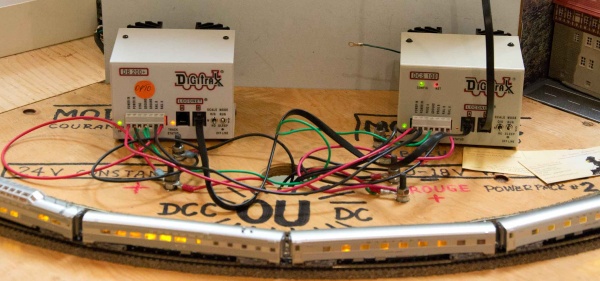

For small layouts simply disconnect the analog power pack and hook up the two wires to the DCC system's booster. It should be noted, that this is the most basic way to get your track running on DCC.

If the existing layout uses multiple power supplies, the conversion is a little more complex. First, all DC (analog) power supplies must be disconnected from the track. Then, all connections to the track must be connected to one or more boosters.

After you have connected DCC booster(s), you'll need to go through your layout's track work to ensure your booster detects short circuits. If there any reversing loops, you'll need to ensure that those are handled properly. This is easily done with the quarter test.

If you're impatient and want to get your locomotives running on DCC before you've converted them all you can set up your layout for Mixed DCC and Analog Operation.

The more wiring topics, see the Wiring for Digital Command Control portal.

Safety

Unlike classic direct current systems, the Digital Command Control booster delivers a lot more power, as high as 10 amps. Compared to the typical direct current (or Analog) setup using multiple power supplies with a maximum output of one or two amps, this is a lot more power. A short can do a lot of damage quickly.

Many older DC/Analog layouts were wired in stages using a variety of wires, colours, and techniques with many splices and connections. This can make troubleshooting difficult, and if doing an upgrade, replacing the wiring is probably a better option.

Sloppy wiring practices lead to new problems, like poor operation, burnt-out decoders, short circuits causing damage, and even runaway locomotives. So, it is better to rewire the layout, document what you are doing, and use adequate wire size for the task.

When converting to DCC, the first and most important thing on the list is to verify that the wiring is capable of handling the increased power capacity you will have. Light gauge wire is not up to the task! Also, check that any toggle switches or other wiring devices are capable of handling the increased current capacity of the DCC System. In most cases, the toggle switches should be removed as you control the trains with DCC, not the layout.

As a rule of thumb, the main source of power to the track, the TRACK or POWER BUS, should be at least 14AWG. Bigger is always better! For drops to the track, 18 to 22 AWG is sufficient. Short lengths of a lighter gauge wire will also be adequate if you need them to connect your track bus to the booster. Please note that the larger scales, like "G" can need significantly larger wire gauges, 12 to 8 gauge is not uncommon as 10 to 20 ampere boosters are often used.

For added insurance, test your track wiring using the Quarter Test. If it fails, find the problem and solve it.

You will see numerous claims that 14AWG wire is overkill and unnecessary. These recommendations are a Best Practice. There are three things to remember: This is not Direct Current, it is not 60 Hertz, and the DCC signal doesn't behave like either of those.

DC/Analog combined with Digital Command Control?

In the early days of Digital Command Control, the ability to run both Digital and Analog simultaneously was considered to be important. This feature is referred to as zero stretching. Using this feature is highly discouraged as it can quickly overheat any DC locomotives on the track.

With low-cost decoders that are easily installed, there's no longer a reason to use zero stretching. Many local hobby shops can install the decoder for you if needed.

Using DC and DCC systems

The two control methods should never be connected at the same time. An oversight can do a lot of damage when the high current DCC signal is accidentally connected to the DC trackage by accident. If there is a desire to use analog control, create a single connection point where your DCC or Analog control system can be connected, and only one can be in use.

Some DCC accessory devices such as Auto-Reverse units used with a reverse loop can be damaged when exposed to a DC voltage. It is not worth the cost when forgetting to remove them from the layout when using DC power.

Power Supplies

- Main article: Power Supply

While you can disconnect your analog throttle/power pack and use it as a power supply for your DCC System, as a rule it is only a temporary solution. The typical power supply used for an analog layout (or your power pack) will not have enough voltage for satisfactory operation, nor can it supply enough current to be of any real use. Avoid using a power pack with Pulse Power.

Obtain a power supply with the voltage and current ratings appropriate for your system. Check your owner's manual for recommended power supplies, or the minimum and maximum voltages, and whether you need a Direct Current (DC) or an Alternating Current (AC) input. In some cases, either will do. For current, you should have at the minimum the current rating your booster is capable of. Larger high current power supplies can be an unnecessary expense. A few amps extra isn't an issue. Using a high current booster meant for large scale locomotives can be a potential disaster with smaller scales.

Common Rail Wiring

This can be tricky with DCC. If the entire layout is wired as one single electrical circuit, or Power District, everything should be fine. Best to be avoided. Also becomes an issue with reversing loops or tracks that cross each other. Common Rail wiring is best avoided.

Power Districts

- Main article: Power District

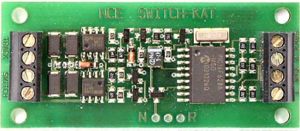

This is the equivalent DCC term for blocks used with Cab Control and other methods of running multiple trains. Their advantage comes from the use of power management devices, which also have circuit breakers in them. This allows for electrically separate sections of track (districts), and should a short occur only that district is affected. All the trains in the other power districts keep running as if nothing has happened.

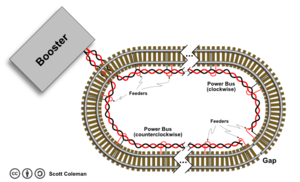

Phasing

Phasing is very important when using multiple boosters. Each booster shall have its own isolated segment of track, called a Booster District.

To verify phasing, a simple DMM on the AC Volts Range will suffice: Place one probe on either side of the gap and read the voltage between the two booster districts. It should be Zero. If there is a significant voltage, the boosters are out of phase. When locomotives bridge the gap between districts, the boosters will start to cycle endlessly if they have Auto Reverse capability. To prevent that, disable the auto reverse function. Then one will shut down. Correcting the signal phase relationship between the two will prevent that from happening.

Connect a heavy gauge return wire between the boosters, as per the manufacturer's instructions, so that return currents can pass through this route instead of your throttle network wiring.

Reversing Sections

- Main article: Reverse Sections

A reversing section is created when the track loops back onto itself, and what was the right rail becomes the left rail. These are dealt with using manual means, such as a switch, or automatically using an Auto Reverser. In either case, gaps must be cut in the rails to eliminate shorts on both sides of the loop. The loop must be large enough that the entire train will be within the boundaries created by the gaps.

See the page on Reverse loops for more details on how to implement them.

Turnouts

- Main article: Turnouts

One of the more troubling issues. The Switch rails must not be electrically connected together. If so, a metal wheel can bridge between it and the Stock Rail, causing a short. Many older turnouts were constructed that way. As DCC systems are much more sensitive to shorts, this will cause problems.

Most, if not all commercial turnouts are DCC Compatible, issues that arise are usually mechanical in nature and easily corrected. Power routing turnouts can cause problems if the point rails are not isolated from the downstream track, allowing the two phases to short.

One way to avoid this is to use a DCC Friendly Turnout, or modify those that can be modified to eliminate this issue.

Conversion Devices

There are a few devices available to help in assisting you in the conversion.

- Lenz manufactured a device designed to protect equipment when Direct Current (analog) was used on the layout at the same time as your Digital Command Control system. This device, the LT100 Digital Circuit Breaker, is wired in series with your analog throttle. One LT100 was required per throttle. The device disconnected analog power to that block when a Digital Command Control decoder equipped locomotive crossed the gap. Otherwise, a short would occur and damage would follow. Once the entire locomotive was in the block, the Digital Command Control signal was disconnected and the analog throttle took over, for seamless operations. As many modellers have completely embraced Digital Command Control, Lenz no longer offers the LT100 Digital Circuit Breaker. Read the manual for the LT100 here.

- If CV 29 is set correctly for Alternate Power Sources, a multifunction decoder should work on direct current. The danger of setting a decoder for alternate power sources is possible loss of control. On a layout that can be powered by Digital Command Control or Direct Current (by disconnecting one power source and connecting another) all the locomotives can suddenly accelerate if the throttle and block switches are not set correctly and direct current is applied to the tracks. Many modellers set the decoder to NMRA Digital Command Control Only operation to prevent a runaway should the decoder encounter a corrupted Digital Command Control signal and switch to Analog operation.

- Some analog power packs with a pulse power mode can damage or destroy a DCC multifunction decoder. Other decoders may behave erratically.

Other Considerations

Occupancy Detection

- Main article: Occupancy Detection

If you have a functioning signalling system, some consideration is needed here. For DCC, a complete rethink and reconstruction may be needed, but if it uses optical methods independent of the track, there should not be too many issues.

Accessory Decoders

- Main article: Accessory Decoder

Accessories, like turnout motors for animation and switches can be hooked up to accessory decoders. This allows you to control your switches and animation through the DCC system.

Motive Power

One of the first steps is converting all the locomotives you wish to run on the layout to DCC by installing a multifunction decoder. This is another advantage of DCC: The multifunction decoder offers total control of the vehicle's performance, which can be custom tailored to your needs.

You don't have to convert your entire fleet, and probably won't. Choose the ones you want to run, and expand the DCC Equipped fleet over time. Some locomotives will be difficult to convert, those can be sent to the display track or sold off, much like a real railroad does.

Analog Conversion is useful if you install decoders but don't have a DCC system in place yet. Later, when you have completed the conversion, consider switching the decoders to NMRA Digital Only operation, to prevent runaways.

Must I Rewire My Layout to Eliminate Blocks?

- No. You can just set all the blocks to select the same cab, and install your DCC system in place of that cab.

- Be sure to disconnect your analog control system before doing that. Never attempt to run analog and DCC at the same time. Bad things will happen no matter how cautious you are.

Some features like reverse loops still require gaps in the rails, but the feature can be automated with a DCC Auto Reverse unit.

If you are converting from direct current (analog) to Digital Command Control, a thorough review of your wiring is in order. See the article on Converting to DCC.

My Turnouts are not Compatible with Digital Command Control

There is no real issue with turnouts and Digital Command Control. All of your trackwork should have no issues with DCC. The problem with switches is short circuits. DCC boosters will react much faster to a short than an old analog power pack would. Check your turnout geometry with an NMRA gauge for proper clearances, and make any modifications needed.

See the articles on turnouts for more information. There are also articles on the popular PECO Insulfrog and PECO Electrofrog and how to make modifications if needed, which also apply to other commercially available switches. There is also an article about the new PECO Unifrog.

The Cost of Converting My Motive Power Fleet for Digital Command Control will be Too Costly!

- No one says you have to convert your entire fleet of locomotives to Digital Command Control immediately.

As you will read below, you only need to convert those you use regularly. It may not be economical to convert some older locomotives, others may have mechanical issues that need to be addressed first. You can expand the fleet of DCC locomotives as time and money allow.

You can also choose from a large number of well detailed, smooth running commercial offerings with DCC already on board, ready to run on your DCC layout. You can even get them with sound on board.

Some modellers decided to convert to DCC, and categorized their fleet of motive power in this manner:

- Locomotive they had no attachment to. These would not be converted to DCC, instead they would be sold off.

- Locomotives they liked. Some may not be possible to convert. Decisions were based on desire to keep the locomotive and ease of conversion. Some would be converted to DCC operation, those where it was not possible or too difficult would either be moved to category 1 or become display models.

- Locomotives they wanted to keep and could be converted to DCC.

In the process, the fleet would often be reduced, and the proceeds from the sale of surplus locomotives help pay for the conversions and purchase of new DCC equipped locomotives. Another advantage was the introduction of new super detailed locomotives to the roster.

Sound is an Unnecessary Expense!

While some don't like sound and prefer silent running, this is one of those issues where many will say that once you have a sound locomotive, it changes everything. It is always a topic that generates a lot of discussion.

Digital Command Control Will Be Obsolete Soon!

The purpose of the NMRA DCC Standard was to define a common protocol which would eliminate the chaos of the command control market. DCC will not be obsolete anytime soon. The standard is defined at the rails, not at the throttle or the decoder.

Command control systems have appeared on the market in recent years which are not DCC Compatible. They may offer interesting features or an engaging user interface, they are also proprietary, with their own hardware and software. The road to DCC was paved with good intentions, and many modellers bought a commercial command control system, only to find their investment was orphaned when the manufacturer or importer ceased doing business. For this reason, command control systems were not popular until the advent of the NMRA's DCC Standards Much like Television was in the early days with competing standards, once the compatibility issue was settled the industry thrived. An NTSC colour set from the 1990s could be transported back in time to the 1950s and work. A black and white set with vacuum tubes from 1961 would have functioned until the day analog broadcasting ceased. (The experience outside of North America would have been different.)

The Internet is much the same. While it is constantly evolving with new services, the underlying protocols have not changed much in decades, allowing for innovation while maintaining compatibility with everyone's equipment and services.

Available Videos

The DCCWiki has a number of curated videos available.

These videos may be helpful: