Zero Stretching

Summary: Zero Stretching is an optional feature which allows operation of a DC–powered locomotive on DCC–powered rails. Also known as 'Zero Bit Stretching' in the DCC specifications and informally referred to as 'Address 00'.

Zero Stretching

It may be possible to power a single analog (non-decoder equipped) model locomotive by itself or in addition to Digital Command Control Multifunction Decoder equipped locomotives through a method known as Zero Stretching. Refer to the documentation for the Digital Command Control system in use, as it is an optional feature.

Many command stations will switch into this mode when a throttle addresses Address 00 (or similar, see the manual for details).

Cautions

This feature was created to make Digital Command Control appealing during the early days following its introduction. It enabled migration to DCC while minimizing fears relating to the costs and installation work required to upgrade. Zero Stretching is not part of the NMRA DCC specification and as such, not all Digital Command Control systems support Zero Stretching.

Some locomotive manufacturers do not recommend operating a non–DCC decoder equipped locomotive on a DCC system. Refer to the instructions before trying your new locomotive on a DCC powered track. Coreless motors will be destroyed by Zero Stretching.

Decoderless Locomotives on a DCC Layout

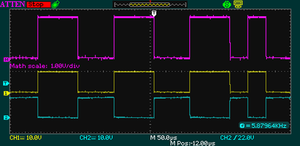

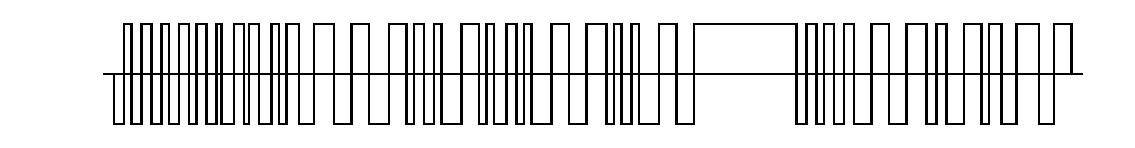

This is an advanced topic. It provides background to Zero Stretching, but is not necessary to understand how it works to use the feature. To operate a locomotive which is not equipped with a decoder, the DCC waveform on the rails is modified. This modification affects only the zero pulse. The DCC waveform has an average DC value of zero, so when zero stretching or analog mode is not in use, a non-decoder equipped locomotive will not move. The DCC waveform normally consists of symmetrical pulses, two of which equal one cycle. Under these conditions no torque is produced in the motor.

As shown, the Zero Pulse consists of a pulse, with a nominal duration of 100 microseconds (µS). The complete cycle is 200µS. Under normal conditions the torque created during one pulse is canceled by the equal duration of the second pulse on the other rail one in the cycle.

How Does it Work?

- Main article: DCC Power

DCC does not have polarity, measuring the DC voltage between the rails results in a value of 0VDC.

DCC is unipolar, meaning only pulses with a positive value are present on the rails. By maintaining one rail with a positive value for a long period of time, a DC voltage between the rails is created. This allows enough time for a motor to develop torque and move the vehicle. Direction is determined by which rail is energized, with time determining the speed.

Implementation

To implement Zero Stretching, the zero–bit cycle is modified. One half of the period can be made a lot longer in duration than the other, which will cause current to flow for a longer period of time. By controlling the rail on which portion of the cycle is longer, direction can be determined. The command station will make the necessary changes to the DCC signal to create the desired effect, based on the throttle's input. As locomotive speed is increased the command station creates more Address 00 packets, with a longer zero stretched segment.

The NMRA Standards permit a zero bit with a duration of 95 to 9900µs (9.9mS), with 100µs being the nominal value. The stretched bit can be a maximum of 12000µS (12mS) or 120 times greater than the nominal.

Since the data packet consists of eight bits, a total of 16 pulses will appear on the rails (two per bit). Which is 1.6mS in total. It is possible for the stretched bit to equal 1.5mS. The speed is determined by the amount of bit stretching and the rate at which Address 00 packets appear. Zero Stretching will not produce as much torque as using pure DC will.

Important Warnings

Caution: Due to the frequency of current reversals and the harmonics present, Direct Current motors heat up more quickly compared to an analog power source, and some motor types can be seriously damaged with only a brief encounter with DCC track. Many motors will buzz and hum when presented with this type of power.

In the early days of DCC there was an unfounded fear that zero stretching would cause motors to overheat, destroying them and melting the body. Those fears were never realized.

- Do not leave locomotives that are not equipped with a decoder on the track

- All direct current locomotives will respond to the signals created by Zero Stretching, which may have unintended results

Coreless Motors

Coreless and other precision motor types should not be used on a DCC powered track unless a multifunction decoder is installed. Normally, current flow is limited by the voltage applied and the Back EMF a motor generates in operation, but the DCC waveform is full voltage all the time. Coreless motors have very low inductance in their windings. The DCC waveform's frequency results in a low reactance which is not enough to limit the current. Coreless motors lack the iron core to sink the heat generated by excessive current flow, which will damage them very quickly.

Bandwidth

As locomotive speed increases, more bandwidth will be demanded of Address 00, which has an impact on response times when more than five decoder equipped locomotives are also in operation. This technique is a power bus bandwidth hog due to the need to constantly send packets addressed to 00.

- Signal Corruption: It is possible that some motors may induce spikes and other noise into the power bus which could cause problems.

Digitrax BXP88

The Digitrax BXP88 will not work with zero stretching. It will disable zero stretching mode in a Digitrax command station automatically via LocoNet commands.[1]

PSX Circuit Breakers

- PSX Circuit Breakers are not compatible. The device relies on DCC power for operation, and may not work at some speed settings.

CVP Products DZB7

Do not use the CVP Products DZB7 ZoneMaster booster with the Address 00 feature. This feature is not supported by the ZoneMaster.

See Also

- ↑ BXP88 Manual: When a BXP88 is powered up on a Digitrax Layout it will automatically disable analog stretching by setting OPSW 20 to Closed in the Command Station. The BXP88 is not compatible with analog mode stretching, preventing the ability to run conventional DC locomotives at address 00. All locomotives need a DCC multifunction decoder to operate.