Energy Storage

{{Article |articlesummary=Some multifunction decoders support an additional external energy storage module to provide backup power when the electrical supply from the rails is interrupted by dirt, bad contact, insulated frogs, etc. This may prevent a locomotive from stalling when travelling over dirty track or turnouts with large plastic frogs, especially at low speed. Short wheelbase locomotives such as 0-6-0 steam locomotives are more susceptible due to their inherently limited number of electrical pickup wheels. Locomotives without flywheels can also benefit from energy storage. Sound Decoders benefit from energy storage systems by preventing dirt and bad rail pickup from causing audible crackling or static coming from the [[Speak |seotitle=Energy Storage |keywords=Multifunction Decoder, energy storage, keep alive |seodescription=Some Multifunction Decoders support an additional external energy storage module to provide backup power when the electrical supply from the rails is interrupted by dirt or poor contact. |termcategory=Mobile Decoder |termdescription=Some Multifunction Decoders support an additional external energy storage module to provide backup power when the electrical supply from the rails is interrupted by dirt or poor contact. }}

|

See the Video. |

Energy Storage

- Also see Inrush Current

Overview

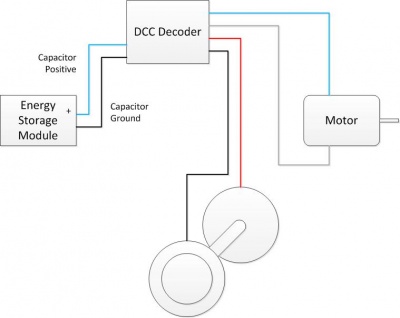

Typically, this function cannot be integrated into a multifunction decoder since storing a useful amount of energy requires a sizeable capacitor. The capacitor (and additional components) must be installed in a separate location in the locomotive and connected to the decoder via wires.

Other manufacturers use different names for the same idea, Zimo simply calls it "energy storage". TCS uses the trademarked name Keep-AliveTM.

Other commonly used names are "Stay Alive capacitor" and "Electronic Flywheel".

Lenz's USP is not an energy storage method. While it does have a small energy storage circuit on-board, the USP decoder has an advanced signal processing system that can read a weak or distorted DCC signal, thus keeping the decoder under control of the DCC system.

How Energy Storage Works

An energy storage module charges a large capacitor while the Digital Command Control signal from the rails is available. Capacitors store voltage, and resist change in voltage by charging and discharging.

When the DCC signal on the track is interrupted, the capacitor begins to discharge which provides decoder power, which in turn supplies the motor. It can only do this for a short period since the capacitor will rapidly discharge. At some point the discharge will cause the voltage across the capacitor to drop below the minimum required for decoder operation.

The capacitor is charged from decoder's internal DC supply. Capacitors can be fitted if access to the decoder's power rails is available. During operation it will discharge into the decoder via those power rails.

Some additional components are required if a large capacitor is used.

Firstly, a large capacitor has a very low resistance when discharged. Placing a locomotive onto a layout with such a capacitor might trigger the command station or booster's short circuit detection. To prevent this a current limiting resistor is needed to control the inrush current. This however causes its own problem in that it limits how much current the decoder can draw from the capacitor. A diode can be added to overcome this limitation.

Secondly, a large capacitor can hold energy for quite a period of time (many minutes) if there is little current draw. A locomotive that was removed from the track and then returned later can remember what it was doing before and set off on its own. While it's away from the track, the voltage of the capacitor may drop to the point where there is insufficient power to turn the motor but enough to retain the decoder's memory that it was moving. To prevent this a discharge resistor can be added across the capacitor's terminals to slowly discharge it when not in use. This effectively resets the decoder so that its speed is zero.

Issues with Energy Storage

A problem many modellers encounter is unexplained "short circuit" conditions when track power is applied. It is believed to be a short circuit because the booster reacts immediately to the inrush current, activating its overprotection circuits to protect itself from damage. Most boosters do not react to a fixed amount of current, they react to the rate of change. This allows them to quickly react to a sudden spike in amperage.

This phenomenon is caused by the inrush currents demanded by the capacitors during charging. To the booster, they appear as a short circuit when the sudden surge of current begins charging the capacitors. The current will decrease rapidly, but the initial surge is large enough to activate the over-current protection in the booster.

Programming Track

Energy storage modules can cause problems on the programming track. The capacitors will absorb the small currents used for programming, resulting in the inability to program the decoder, or erratic results. Some decoders, such as ESU's, have the ability to disconnect their Power Pack® module during programming.

Two possible solutions are:

- Disconnecting the module before programming, either physically or with a small switch

- A 100µH choke in series with the module (XL ≈ 5Ω)

See the section on Programming Issues for more information.

Construction

Storage Components

The storage component is usually an electrolytic, tantalum, or a double-layer capacitor. The most common type is electrolytic because they are low cost and readily available. Electrolytic and Tantalum capacitors are polarity sensitive, installing them incorrectly will destroy them[1] Tantalum capacitors are also sensitive to heat stresses, so use care during soldering.

Double-layer capacitors (often referred to as gold capacitors) offer much denser energy storage than conventional capacitors but at a higher price and limited voltage rating. Usually at least four double-layer capacitor "coin cells" must be combined for this application. The benefit is the storage capacity can be 10 to 100 times more than with electrolytic capacitors of the same physical size. Despite the name, "gold capacitors" contain little, if any, gold.

Regardless of the type, these capacitors are polarized, meaning that they must be wired correctly.

For HO or OO gauge a capacitor as small as 470μF will provide some benefit but sizes of 2200μF and above are preferred. 2200μF will be able to supply power to a locomotive for a few tenths of second, enough to get it over a piece of dirty track at low speed. The endurance of larger capacitors of over 10,000μF can be measured in seconds.

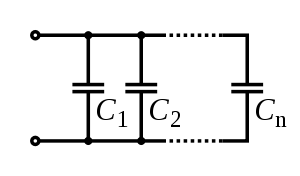

Many locomotives will have insufficient or oddly-shaped space available to install a large capacitor but it is possible to use multiple smaller capacitors instead. They can be wired in parallel to increase the energy storage capacity or wired in series to increase the voltage rating. A combination of series and parallel wiring is also permitted.

The capacitor must be rated for at least 25V for the smaller gauges and 35V for the larger gauges (O and above). This rating is the maximum voltage that the capacitor can withstand without damage. If multiple smaller capacitors are used and they are wired in series then only the sum of the ratings needs to be at least 25V. For example, two 16V capacitors wired in series would be suitable for the smaller gauges because combined they have a rating of 32V. If the capacitors are wired in parallel then all of the capacitors must meet the voltage rating requirement.

Series and Parallel as Applied to Capacitor Circuits

Capacitors behave the exact opposite to resistors in these circuits.

Capacitors in Parallel

Total Capacitance of capacitors in parallel is the sum of the individual capacitors. Three 100μF capacitors are the equivalent of one 300μF capacitor.

The voltage rating is equal to the lowest rated capacitor in the group.

Capacitors in Series

When capacitors are wired in series, the total capacitance is reduced. The voltage rating is equal to the sum of all the capacitor voltage ratings. For example, two 50V capacitors in series are the equivalent of a 100V capacitor. This is important for the low voltage ratings of Super Capacitors often used in homemade energy storage solutions.

The total capacitance is calculated using the formula: 1/CTotal = 1/C1 + 1/C2 + 1/C3 ....

Example: Two 100μF capacitors in series equals 50μF total

Two 50μF capacitors in series:

- 1/C = 1/50 + 1/50 = 0.02 + 0.02

- =1/0.04

- = 25μF

A 50μF in series with a 200μF capacitor:

- 1/C = 1/50 + 1/200 = 0.02 +0.005

- =1/0.025

- = 40μF

Wiring

The typical application is a capacitor, with a resistor and diode, wired from the Positive/Common wire (Blue) to the multifunction decoder's ground. This places the circuit just after the diode matrix which provides DC power for the various components of the decoder

There is no NMRA standard for wiring energy storage modules to multifunction decoders, and there are no known standard wiring harnesses or connectors that include the necessary connections. On many decoders the user must solder additional wires directly to circuit board, often requiring removal of some of the insulating plastic sleeve. More proficient soldering skills are needed to perform this task than are typical for installing a multifunction decoder.

DCCconcepts and Zimo use the convention of black wires for the energy storage ground and blue wires for the energy storage positive. TCS uses a similar convention but the ground wire is black with a white stripe.

The Lenz system uses 3 wires for U+ (blue), charge (pink) and ground (brown).

Connections

- Thoroughly read and understand the instructions provided by the manufacturer.

The energy storage module is fitted between the blue common lead and the 0 or ground lead. Many decoders will not have a pad marked Negative or Ground. To complete the circuit the module must be connected across the diode matrix that provides power to the decoder. This can be done by soldering to the cathode of one of the diodes in the matrix. This must be done on the decoder side, not the track side of the matrix. Be aware that one of the diodes in the matrix is the signal pick off for the decoder. That is not one to be used.

LokSound Multifunction Decoders

ESU has stated that they will not warranty LokSound decoders damaged by poor or improper soldering techniques. They strongly advise you to consider carefully the need for adding capacitors.

The LokSound 5 Manuals contain information and wiring diagrams on page 42.

CV Changes

For proper operation, disable Analog Conversion mode (in CV29), and set the packet timeout value in CV11 to "0." As always, consult the literature that came with the module for any CV changes required.

Analog Conversion Mode

Energy storage is not supported in Analog Conversion mode because there is no way for the decoder to distinguish between a command to stop (0V sent by an analog throttle) and a dirty section of track (0V received by the decoder). A decoder fitted with energy storage and with analog conversion enabled will still work normally, it will simply stop immediately when it receives no power.

Theoretically, it could be supported with the decoder assuming 0V means coast for a short period and then stop. The disadvantage being that there would be no way to cause an emergency stop.

Programming Issues with Energy Storage Modules

There can be unintended issues arising from the use of a "keep alive" module. In many cases the programming track output will only have power available during a programming read/write cycle.

The short, low energy pulses used during programming may be absorbed by the capacitor, leading to programming problems. The capacitors do not charge as they normally would, leading to issues like this.

The simplest way around this problem is to mechanically disconnect the capacitor from the decoder prior to programming. If the capacitor is soldered to the decoder, disconnecting is not an easy task. During installation a switch can also be installed which can break the connection to the capacitor. Mounting the switch in an easily accessible location may not be possible.

One proposed solution is the addition of a 100μH inductor (also called a choke) in series with the capacitor. It will slow the current flow into the capacitor, which will not be an issue during normal operation. During programming, it can reduce the current flow enough to make successful programming possible.

As inductors are not polarity sensitive, it can be easily fitted to either wire feeding the capacitor.

Some decoders have the ability to disconnect their energy storage modules when they go into their programming mode.

ESU LokSound 5

The ESU LokSound 5 decoders have the ability to disconnect the ESU Power Pack® when a programming command is received.

For ESU Power Packs, disable the Power Pack on Aux 6 or Aux 7:

- CV 31 = 16

- CV 32 = 0

- CV 339 = 0 or CV323 = 0 for Micro or Direct

Re-enable the Power Pack once programming is complete:

- CV 31 = 16

- CV 32 = 0

- CV 339 = 31 or CV323 = 31 for Micros or Directs

This process uses an Indexed CV. Some DCC systems may experience issues when attempting to program decoders with Indexed CVs.

Do not construct your own energy storage module for use with ESU LokSound decoders. Using modules' other than the ESU Power Pack with a LokSound decoder can result in destruction of the decoder.

Availability

DCCconcepts, Lenz, TCS and Zimo make multifunction decoders that support energy storage.

DCCconcepts refer to energy storage as "Stay Alive", they supply some decoders with the storage module included in the package or they can supply them separately. All of their current decoders support Stay Alive and come pre-wired with two additional wires to make it simple to attach their module without soldering directly onto the decoder's circuit board.

Lenz Gold series decoders which support USP also support energy storage using their POWER1 or the larger POWER3 modules.

TCS makes energy storage modules and decoders with integrated on-board storage. All of their decoders manufactured after February 2012 are Keep-AliveTM ready or have it on-board. Some of their decoders require soldering wires together to connect the storage module (-KA series) or simply plugging them together with a quick connector (-KAC series). They also supply versions with a harness for their WOWSound multifunction sound decoder

Most Zimo decoders support energy storage using their SPEIKOMP kit and they supply instructions for building completely DIY modules allowing greater flexibily for capacity and physical size. Some of their decoders have the built-in support circuitry and only require the capacitor itself to be added whereas others require additional external components.

Comparison of Energy Storage Systems

| Manufacturer | Decoder Interface |

USP | DIY[2] | Max Capacity (μF) |

Module/Kits | Supported Decoders | Capacity (μF) |

Ready Made |

Storage Technology |

Solder to Pads |

|---|---|---|---|---|---|---|---|---|---|---|

| DCCconcepts | No | No | SA3, xxxSAP[3] | All | Yes | No | ||||

| Digitrax | PX108-2 | For use with a 2 pin PX socket or solder pad | 330000 | Yes | ||||||

| PX108-6 | For use with a 6 pin Sound Harness | |||||||||

| PX108-6F | For use with a 6 pin Function Harness | |||||||||

| PX108-10 | For use with a 10 pin Sound Harness | |||||||||

| PX112–2 | For use with a 2 pin PX socket or solder pad | 160000 | ||||||||

| PX112–6 | For use with a 6 pin Sound Harness | |||||||||

| PX112–6F | For use with a 6 pin Function Harness | |||||||||

| PX112–10 | For use with a 10 pin Sound Harness | |||||||||

| ESU | Yes | No | PowerPack-mini | Yes | Yes | |||||

| PowerPack Maxi | Yes | Yes | ||||||||

| Iowa Scaled Engineering | Yes | Yes | Run-N-Smooth[4] | N Scale, prevent decoder resets. | 950µF | Yes | Capacitors | Yes | ||

| Lenz | Yes | No | POWER-1 | GOLD, GOLD Mini | Yes | Yes | ||||

| POWER-3 | Yes | Yes | ||||||||

| NCE | No | No | No Halt | Yes | No | |||||

| Soundtraxx | No | No | Current Keeper | Yes | No | |||||

| TCS | Hardwire | No | No | KA1 | All -KA series decoders | Yes | No | |||

| KA2 | Yes | No | ||||||||

| KA3 | Yes | No | ||||||||

| KA4 | Yes | No | ||||||||

| 2-Pin Quick Connector | No | No | KA1-C | All -KAC series decoders | Yes | No | ||||

| KA2-C | Yes | No | ||||||||

| KA3-C | Yes | No | ||||||||

| KA4-C | Yes | No | ||||||||

| Auxilary Harness | No | No | WAUX-KA1 | WOWSound Decoders | Yes | No | ||||

| WAUX-KA2 | Yes | No | ||||||||

| WAUX-KA3 | Yes | No | ||||||||

| WAUX-KA4 | Yes | No | ||||||||

| On-board | No | No | Integrated | All KAT and KAM series decoders | Yes | No | ||||

| Zimo | No Special Port | No | Yes | 10,000 | SPEIKOMP, ELKOSODR | MX618, MX620, MX621, MX622, MX63, MX630, MX64, MX646, MX647, MX648 | 470, 6802 | No | Electrolytic | Yes |

| 25V Limited Port | No | Yes | 10,000 | ELKOSOMT | MX631, MX632, MX644 | 470, 6802 | No[5] | Electrolytic | Yes | |

| 16V Limited Port | No | Yes | 10,000 | ELKOSOPL | MX633, MX643, MX645 | 680, 18002 | No[5] | Electrolytic | Yes | |

| 16V Unlimited Port | No | Yes | Unlimited | ELKOSOGR | MX695, MX696 | 10,000, 20,000[6] | No[5] | Electrolytic | Yes | |

| GOLDSOR | 140,000 | No[5] | Double Layer[7] | Yes | ||||||

| GOLMRUND | 140,000 | Yes | Double Layer[7] | Yes | ||||||

| GOLMLANG | 140,000 | Yes | Double Layer[7] | Yes | ||||||

| GOLMREG | MX645P22 + ADAPLU22 | 140,000 | Yes | Double Layer[7] | Unknown |

Supported Multifunction Decoders

The following decoders will support installation of an Energy Storage module. This list is not a complete listing.

- DCCconcepts: All multifunction decoders (specifically those listed as xxSAx)

- Lenz: GOLD series and GOLD mini series

- TCS: All -KA and -KAC (all decoders manufactured after February 2012), WOWSound.

- Zimo: All MX618, MX620, MX621, MX622, MX63, MX630, MX631, MX632, MX633, MX64, MX640, MX642, MX643, MX644, MX645, MX646, MX647 families

Videos

Video: Demonstration of a Keep-Alive by TCS

Install a TCS Keep-Alive with a Loksound Select Direct Sound Decoder

Connecting a CurrentKeeper to SoundTraxx Decoders

Stayalives

How to make a Stay Alive Capacitor Unit (Hornby TTS Sound Decoder and Others)

Further Reading

External Sites

- How to Add Current Keeper to Soundtraxx Tsunami Decoders

- Stay Alive for Decoders

- Capacitors, Current Keepers, Keep Alives, Oh My! Tips and tricks for programming ESU LokSound 5 Decoders

- Lenz Power1 Instruction Manual

- Run-N-Smooth by ISE

- ↑ These devices are polarized, connecting them incorrectly will result in failure of the capacitor. The electrolyte from an electrolytic capacitor can cause corrosion, damaging the decoder.

- ↑ DIY indicates that the manufacturer supplies instructions to build energy storage module from scratch

- ↑ All DCCconcepts decoders ending in SAP include the Stay Alive module in the package

- ↑ ISE's Run-N-Smooth is meant to provide a very short duration of power to overcome wheel contact and track issues. It isn't designed to function as an energy storage module in the traditional sense.

- ↑ 5.0 5.1 5.2 5.3 Modules are not supplied ready-made. Since only a single capacitor is required, there is nothing to make unless multiple capacitors are to be combined when more storage capacity is desired.

- ↑ More capacitance is available by combining capacitors in parallel

- ↑ 7.0 7.1 7.2 7.3 Double Layer capacitors are often referred to as "Gold Caps."