Turnout Motors

Summary: A Turnout Motor (or switch machine) is a device which is used to remotely align a turnout. Using an Accessory Decoder, turnout alignments can be accomplished using a throttle and automatically setting a route is possible.

|

See the Video. |

What is a Turnout Motor?

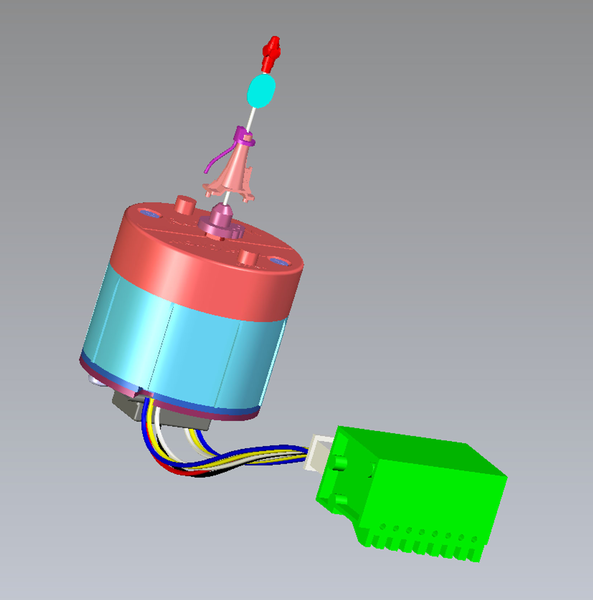

A Turnout Motor or Switch Machine is a mechanical device which electrically controls a turnout's alignment. There are several types, slow motion machines, such as the pictured Tortoise by Circuitron, soleniod types, and motor driven screw types.

- A slow motion machine uses a stall motor with large ratio gearing. The motor is constantly energized, drawing very little current when stalled. When the switch points close, the motor stalls and holds them in position.

- A 3-wire solenoid has two coils (twin coil) and an iron slug (the armature) at their core. By energizing one coil, the armature is pulled into the coil. The slug is connected to a mechanism which is connected to the switch. The coil is only energized momentarily, as it will overheat and burn out if continuously energized. The armature is connected to a rod to transfer the motion. This connects to a mechanism which allows the position to be held (latched) until changed. This mechanism, usually a lever, allows the throw of the armature's motion to be adapted to a more useable form. Contacts are often provided, which can be used to control the frog.

- A 2-wire solenoid has one coil and a permanent magnet at its core. By energizing the coil with DC current, the magnet is pulled one way. By reversing the DC polarity, the magnet is pulled the other way. The magnet is connected to a mechanism which is connected to the switch. The coil is only energized momentarily, as it will overheat and burn out if continuously energized.

- A limit-switch DC motor type has a can motor with gearing to operate a push-pull actuator. The gearing can be regular gears or a screw (or threaded rod) connected to its drive shaft. For the screw-type, a nut is threaded onto the screw. As the motor turns, the nut moves along the screw. A mechanism connected to the nut is used to actuate the points. The motor is turned off by internal limit switches when the motion required is completed.

- A rotating solenoid has one coil and a rotating permanent magnet at its core which turns a rack and pinion style gear and moves the turnout actuator. This relies on a half-wave rectified DC power source. Each half cycle of the DC power gives the magnet a kick in one direction of rotation and its momentum carries it round for the other half cycle. Reversing the polarity reverses the direction of spin and the actuator moves the other way.

Tortoise Switch Motor, with tan coloured PCB.

- Radio Control Servos can also be used as turnout motors. Special DCC accessory decoders are available with servo drive outputs.

- Rotary Solenoids employ a ratcheting mechanism, such as those used in the Ives/Lionel E-Unit.

Many switch machines have SPDT contacts that can be used for power routing, signals, etc. One application is routing power to the frog, to maintain the correct phase.

The solenoid types make a loud noise or snap when actuated.

PECO Turnouts

If you plan to use PECO turnouts on your layout with a turnout motor, remove the spring which locks the switch rails in place. PECO has published information on the web on how to do that. It is possible to remove the spring after the turnout is installed, should that become necessary. See the video below for more details.

Turnout Motor List

| Turnout Motors | DCCWiki.com | ||||

|---|---|---|---|---|---|

| Type | Manufacturer | Model | Accessory Switches | Mounting Type | Notes |

| Slow Motion |

Circuitron | Tortoise (See Note) | 2 SPDT | Underside | Edge Connector: EDAC 306-010-500-102 |

| SMAIL | Integrated Accessory Decoder | ||||

| DCC Cconcepts | Cobalt | 2 or 3 SPDT | Underside | Optional AD1 integrated DCC decoder. | |

| Twin Coil |

Atlas | "Snap-Switch" Turnouts | None | Integrated | Turnouts with integrated, side mounted motors |

| 52, 53 | Side | Left and right motors for Atlas manual HO Code 100 turnouts | |||

| Hornby | PR8014 | Underside | Surface mount with R8015. | ||

| PR8243 | Side | For use only with Hornby turnouts | |||

| Peco | PL10 | Underside | Surface mount with PL12. | ||

| PL10+PL13 | 1 SPDT | ||||

| PL10+PL15 | 2 SPDT | ||||

| PL11 | None | Side | |||

| PL-1000 | Underside | Can be mounted on the table top. | |||

| PL-1001 | 2 SPDT | Includes the microswitch | |||

| PL-1005 | Adds the microswitch to the PL-1000 | ||||

| Seep | PM-1 | 1 SPDT | Under | ||

| PM-2 | None | ||||

| PM-4 | 1 SPDT | Self-latching version | |||

| Single Coil |

Kato | All N Scale Turnouts | None | Integrated | Turnouts with motors integrated into base |

| Most HO Scale Turnouts | |||||

| 2-503, 2-504 | Side | For HO Turnouts: 2-840 and 2-841 | |||

| Limit-switch DC motor |

Aristo-Craft | 11299 | 1 SPDT | Side | For G scale use |

| Fulgurex | 2 SPDT | Surface | Can be mounted underneath to the side. Two additional SDPT switches used as internal limit switches. | ||

| Rotating Solenoid |

LGB | 12010 | None | Side | For G scale use |

| 12010+12070 | 2 SDPT | ||||

| Rapido | Rail Crew 320101 | 2 SPDT | Under | HO Scale rotating target/stand included | |

| Servo | Tam Valley Depot |

SSD001 | None | Under | SWR001 available for mounting servo |

| SSD001+RSR001 | 1 SPDT | ||||

| SSD001+RDR001 | 2 SDPT | ||||

Circuitron Tortoise Notes

Notes: According the a note on the Circuitron website, changes have been made to the Tortoise.

- The supplier of the low current motor has changed after the original manufacturer ceased operations. The newer Tortoise machines operate in the same manner, any differences should be unnoticeable.

- The supplier of the circuit boards has changed. The new Tortoise features an FR-4 epoxy laminate board which is GREEN on both sides.

The green boards make it easy to distinguish between old and new production Minor Differences:

- The new boards have a wider, industry standard connection flange whereas the older tan boards were undersized. This may create problems if you are trying to fit a new TORTOISE™ into an older undersized edge connector.

- Fits any industry standard 8 position edge connector.

- Hole spacing changes with a new row of holes added. Allows use of Molex style connectors or the 3.81mm spaced terminal blocks CIRCUITRON already sells and uses on their SMAIL™

- Current draw when stalled is 16mA or less.

Circuitron Support

Application Notes

- AN-6000-02 Using the Internal SPDT Switches of the TORTOISE™

- AN-6000-03 Using the TORTOISE™ with Peco Turnouts

Instructions

- 800-6000 TORTOISE™ Slow Motion Switch Machine

- 800-6200 SMAIL™ Slow Motion Actuator with Integrated (DCC) Logic

Circuits4Tracks

Circuits4Tracks offers a Switch Machine Interface designed for easy connections to a Tortoise and includes connections to power the frog.

Controlling Turnout Motors with Digital Command Control

Control of turnouts using your throttle or a computer running software such as JMRI is possible using a accessory decoder. Accessory decoders can also offer features such as routes, which can automatically align several turnouts. The same is possible with a computer, some command stations may also support routes.

Accessory Decoders

Below is a selection of accessory decoders which can handle turnout motors, broken down by manufacturer.

The products listed below are capable of handling turnout motors. However,, most products are capable of other tasks such as block detection, push button control, etc. Please see the various manufacturers products pages and manuals for further details.

Circuitron

The SMAIL (Slow Motion Actuator with Integrated Logic) is a DCC enhanced Tortoise slow motion turnout motor. It incorporates an internal NCE Switch-It decoder. Available with the edge connector or an optional factory installed terminal block.

Commands and power are provided by two wires from the track Power Bus, or a dedicated DCC power bus.

Digitrax

See Digitrax Products page for full details on Digitrax's products.

As these are Digitrax products, they may also be LocoNet devices.

- DS74 - Replacement for the DS64. Controls snap and slow motors. Operate your turnouts directly through any DCC system that has turnout control.

- DS64 - No longer available. Controls snap and slow motors. Operate your turnouts directly through any DCC system that has turnout control.

- DS44 - Basic quad accessory decoder for slow motion turnout machines

- Cheapest per turnout, but operates only via throttle commands (and/or computer).

- DS51K1 - Accessory decoder for single Kato Unitrack turnouts

- DS52 - Dual accessory decoder for bi-polar, snap switches, or slow-motion machines

- DS54 - Quad accessory decoder for snap switches or slow-motion machines. Has four outputs and eight inputs which be used for positive feedback of switch position, or other uses.

- No longer available (replaced by the DS64)

- DM1 - DC motor adapter was required to use the DS54 to control bi-polar turnout machines.

Lenz

LS100 and LS110

- 4 DC Outputs with common positive

- Momentary (0.1 to 15 seconds), Continuous and Flashing (4 to 0.5 Hz) options

- Always programmed to a group of 4 turnout addresses. e.g., 1-4, 5-8, 9-12

- Can use DCC track power or external supply

LS100 and LS110 are identical except the LS100 supports the Lenz RS Feedback Bus

With the addition of LA010 output adapter the 3 wire common positive can be converted to a two wire polarity reversing output. A circuit to do the same job as an LA010 is on the Lenz Accessories page

LS150

- 6 AC Outputs for twin-coil snap action

- Motorized switch machine like KATO Unitrack turnouts can be used with simple addition of 2 diodes.

- Each output can be given an individual 'Turnout address'

- Outputs can be set to be on for 0.1 to 10 seconds

- Needs external AC supply - Max 16 V (Use a transformer LESS than 45VA or add a 10Ω resistor)

ESU

SwitchPillot

SwitchPilots are available in several versions. They are also multi-protocol, so they can be used with DCC or Motorola based command control systems. They also support RailCom.

SwitchPilot V2.0 is mainly a solenoid oriented device. It can control up to 4 solenoids or 2 servo motors. It can also control lamps, with features such as fading to simulate a signal light going out.

Another feature is the SwitchPilot Extension, which can be used to power frogs

NCE

Switch-Kat Switch-It

Tam Valley

QuadLN

The QuadLN_S is an accessory decoder for LocoNet with programmable servo drivers. The basic unit can control 4 servos, the addition of an expansion board expands that to 8. Two or three positions Eight inputs/outputs Four additional expansion outputs which can drive a 5V relay board or another 4 servos Optional signal board can up to 24 LEDs

Wiring Accessory Decoders

Hints, tips, and suggestions on wiring accessory decoders for use with turnout control.

Use A Separate Booster or Bus for Control

Or a separate power bus from a power management device for the accessory decoders instead of the power bus for the rails. The reason is simple: If the accessory decoder is controlled by your track bus, if a turnout shorts out your track, the movement of the turnout will stop. When power is restored to the track, the short will cause immediate shutdown of the track bus again. Because the turnout motion has stopped, the short will never clear itself. With separate power and signalling, the accessory decoder will still function during a track short.

For example, use LocoNet or another bus for control with a separate power source, so track bus problems don't cause a feedback loop when a turnout causes a short.

Do not power the accessory decoder from the track bus, and if possible, do not use the track bus for control signals. DCC power is costly, a simple power supply is a cheap source for power.

See the track wiring pages for details, and your owner's manuals for wiring and termination recommendations.

Power Routing with Switch Machines

Switch machines may have accessory contacts for controlling signals and routing power to the frog. Manually operated ground throws may also have contacts that can be used for that purpose.

Tortoise wired to route power to the frog. Drawing courtesy of Fast Tracks. Used with permission, ©Fast Tracks

Ground Throw wired to provide power routing to a DCC Friendly Turnout. Drawing courtesy of Fast Tracks. Used with permission, ©Fast Tracks

Videos

Removing the Spring from a PECO Turnout

Installing a Rail Crew Turnout Motor

Video by Rapido Trains from YouTube demonstrating the installation of a Rail Crew turnout motor on a Peco Electrofrog turnout.