Reverse Sections

Summary: A section of track which allows a train to reverse direction is a Reverse Loop, sometimes called a Balloon Track. Electrically they represent a problem on the layout, as Rail A meets Rail B at the turnout, causing a phase mismatch. Careful wiring, installation of gaps, and a method of switching rail phase are required. Wyes also require this attention.

|

See the Video. |

Reverse Sections

When you heard about Digital Command Control and all its advantages, they told you there is no need to worry about polarity issues and reversing sections. Not quite true!

Except for 3-rail track, all electric train layouts have to be specifically wired when it comes to reversing sections of track. A reversing section allows a train to enter in one direction, and leave on the same track heading back the way it came.

Reversing sections include: Wyes or triangles, turntables, and reversing loops (balloon tracks).

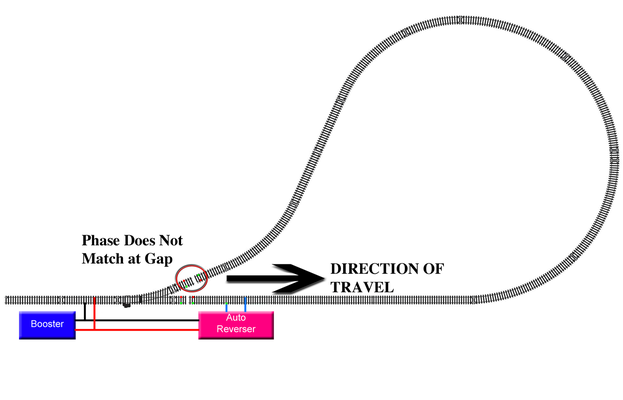

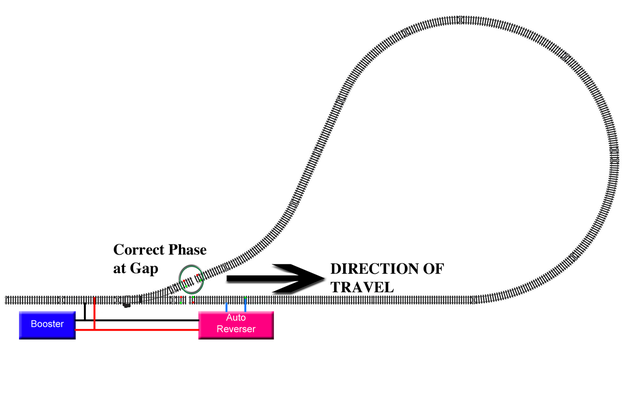

Digital Command Control has phase issues, and a reversing section will cause a dead short if not wired correctly. With DCC, Rail B is held to ground while Rail A is Positive, which then flips (Rail A is held to ground and Rail B becomes Positive) to construct the DCC digital waveform.

Since Digital Command Control uses a digital signal on the rails to provide both commands and power to the decoders, there is no polarity, as the signal consists of only logical high and low values. There is no concept of polarity with digital, as there are no positive or negative values. Phase refers to the condition that the state of Rail A is always the logical opposite of Rail B.

With traditional Analog DC layouts, the main line's polarities must match the reverse loop when the train exists to avoid a short circuit.

Unlike Analog, DCC changes the phase relationship of the loop to match that of the main line.

In a traditional DC Powered layout, a reversing section is insulated from the rest of the layout. It is powered through an independent reversing switch. The train enters the reversing section and, whilst the train was totally inside the reversing section, the polarity of the main line was reversed. When the train leaves the reversing section, it continues as normal.

The DCC difference is an automatic phase inverter (or autoreverser) controls this process. As a train enters or leaves the isolated reversing section, the device detects the short circuit created and changes the phase relationship of the reversing section to the main line. This happens quickly enough that the train continues on its way unimpeded.

For proper operation the reverse loop must be large enough to contain the entire train, including any powered units functioning as pushers, between the insulated gaps.

Direction of travel is determined by the multifunction decoder, not by the track.

This behaviour has some side effects that bear consideration:

- A single reverser may be used to control more than one reversing section. The constraint is only one train may be entering or leaving reversing sections controlled by a single reverser at a time.

- The reversing section must be long enough to contain all of the train that may trigger the short – engines, cars with electrical circuitry, cars with conductive wheels.

- Care must be taken that the current capacity of the booster and wiring is sufficient so that the reverser detects the short in a timely manner and performs its function. If the booster or power management device acts too quickly things will not work well.

The LDT KSM-SG is different than most reverse-loop modules, the reversal phase of the reverse-loop will be performed without a short circuit due to two sensor-tracks located at the entrance and at the exit of the reverse-loop.

Application Example 1: Reverse Loop

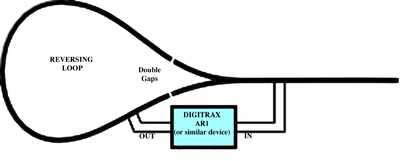

The Digitrax AR1 is a device which provides automatic reversing of track phase whilst a train passes through a reversing section. Although the AR1 is used in these examples and diagrams, there are many other products from various manufacturers which work just as well (and some argue better) than the AR1. We highly recommend you check out reversing units from various manufacturers and vendors before making your final decision. A Frog Juicer can also be used in this application.

Connection is simple via the two pairs of wires: one pair brings track power to the AR1 (shown on the right), the feed can be from the track or the power bus, the other pair feeds the loop from the AR1. The gaps in the rails are essential: They isolate the two opposite DCC signal phases (see DCC Tutorial (Power)). Electrical gaps must exist in both the places shown. These gaps can be made by using insulated rail joiners or cutting the rails and filling the gaps with an insulated material such as styrene.[1] Other devices available on the market work in much the same way.

When a locomotive bridges the gap, rather than stalling or shorting out the track bus, the autoreverser inverts (switches) the phase relationship when needed.

Because of the double-gaps, it does not matter whether the turnout has an insulated or a live frog (such as the PECO Insulfrog or Electrofrog type turnouts).

Application Example 2: Reversing Triangle or Wye

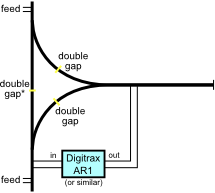

Whereas reversing loops are rare on full-sized railways, triangular junctions, or wyes are quite common. The AR1 can also be used for these. The triangle may connect to a separate line (as in full-sized practice) or may simply be a convenient spur siding.

A wye was often used to turn a locomotive where a turntable was not available.

The track feed connects to the AR1 input just as in the reversing loop case. The AR1 output feeds the spur. The two double gaps on the right (before the turnout) are essential to isolate the different power phases.

It is important to note that it is not possible to make any other feed connections to the spur other than via the AR1 unit.

The double gap on the main line marked with an asterisk () is required if the turnout has a live frog.

Troubleshooting a Reverse Loop

Gaps

Gaps are required to isolate the loop from the track leading to it. They can be created using an insulated rail joiner to connect sections of track, or by cutting a gap with a razor saw.

The gaps must not be staggered to prevent other issues from occurring. Definite boundaries between the loop and the inbound/outbound track are required. It is also important that the insulating material, such as that of an insulated rail joiner, not be proud of the railhead. Auto-reversers require a hard short to work, and the wheel's tread must bridge both sides of the gap simultaneously. This is usually an issue with vehicles which have a function decoder or lighting installed and receive their power from only one truck

If the gap is created by cutting the rails, fill the gap with a non-conducting material such as styrene. Filling with an appropriate thickness of styrene will prevent the gap from closing up during expansion cycles, or wheels falling into the gap. While the expansion of your rail is not very much, it can be enough to close the gap. Movement of wooden benchwork during expansion and contraction contribute much more. Carefully shaping the styrene filler can create an almost invisible gap in the rails. Just insert the spacer, use a little ACC to bond it to the rails, and shape it using files and knives.

Electrical Issues

As with all trackwork, proper wiring is important. Poor wiring impedes operation of an autoreverser by limiting the current flow. It requires a short circuit to happen before it will act, with enough current flow to trigger it. The autoreverse unit must be wired correctly, using the main power bus wiring. It should not be connected using light gauge wires directly to the track. Some auto reverse units may not work correctly if wired after a power management device. Feeders should also be used as needed.

Adjustments or changes may be needed to ensure it works, as some boosters may trigger faster than reverser. The reverser should be the first and only device to trigger when a phase mismatch occurs.

If the reverse loop is feed by a different booster than the lead in track, the use of a proper sized booster common is important. Limiting the current with poor wiring between the boosters causes issues.

The auto reverser may need some adjustment to the trip point, if possible. If the trip current is too high, the unit may not react all the time, or only under certain conditions.

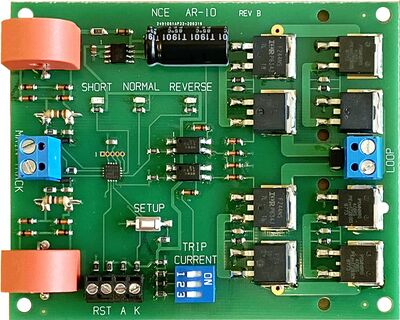

Reversing Units

(Please use this area to list and provide links to devices which will handle reversing sections.)

- Digitrax PM42

- Digitrax AR1

- Lenz LK200 (In German)

- LDT KSM-SG

- MRC AD520

- OpenDCC Reverser

- Z21 Multi Loop Fleischmann/Roco

- Zimo MX7, MX7/3

- Power Shield X and OG-AR from DCC Specialties

- DCC Dual Frog Juicer and Auto-Reverser from Tam Valley

- KSM-SG-F by Littfinski DatenTechnik (LDT)

- NCE AR10

- Hornby R7327 (Replacement for the HM7050)

Further Reading

Videos

Video: Do you Have a Reversing Loop?

Digitrax AR1 Auto Reversers. Tips and Setup Tricks.

- ↑ Filling the gap level with the railhead is good practice; It allows a metal wheel to pass over the gap without falling into it and making a connection across the gap.