Multiple Unit Consisting

Summary: Multiple Unit Consisting allows the modeler to faithfully replicate prototype operations by creating a consist of several locomotives to haul a train. This has the effect of creating one large higher horsepower locomotive controlled by one engineer. With Digital Command Control, a Multiple Unit Consist can be easily created and operated from one throttle.

|

See the Video. |

Note: Before creating a consist, be sure to match up the loco speeds.

Consisting Overview

- Basic Consisting: All multifunction decoders in the consist share the same Primary or Extended address

- Advanced Consisting: A Consist address has been set in the multifunction decoder using CV19[1]

- Universal / Command Station Consisting: The consist is created and managed by the command station

Terminology

There are a number of terms used with consisting. There are the "official" terms the NMRA uses, and those employed by the manufacturers. Unfortunately, the two don't mix well.

NMRA DCC Terminology

See the NMRA website for the RP 9.2.1 Extended Packet Formats for more details.

Terms

- A Consist is a group of multifunction decoders linked together, such as several Diesel-Electric locomotives in a Multiple Unit lashup.

- Consist Address: The address to which several linked multifunction decoders will respond. For example, the consist address is 100, and that address controls multifunction decoder addresses 1234, 5678 and 90.

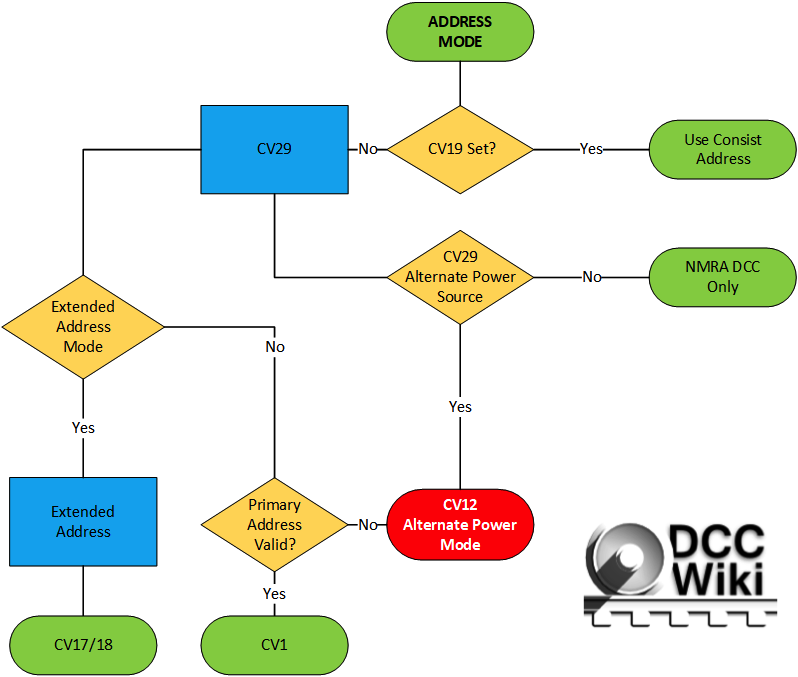

- The Consist Address resides in CV19. If that CV has any value other than zero (0), the Primary and Extended Addresses are overridden by the address stored in CV19. This CV is usually changed by the command station when an Advanced Consist is created or cleared.[2]

- Consist Addresses range from 1 to 127, usually beginning at 127 ($7F) and decrementing as consists are created.

- If the address is greater than or equal to 128 ($80), the vehicle will be running in reverse.[3]

- Consist Control Instruction: A subset of instructions used to send commands to a consist. Used to assemble or dismantle a consist.

- Basic Consisting: An early form where all decoders in the consist share the same address.[4]

- Universal Consisting; Command Station Based: The command station builds and manages a list of locomotives which are part of a consist. When a command is sent, the command station sends a packet to each unit in the lashup. This consist is not portable, when the locomotives are moved to another layout the consist ceases to exist. Once back on home rails, they are again a consist.

- This method will work with a small number of locomotives. On a large layout with multiple locomotives consisted, network latency becomes an issue, and erratic operations result due to the volume of packets that must be transmitted.

- Sometimes called "the old way" or "brute force" consisting.

- A variation on Universal Consisting is Throttle Based Consisting. This variant relies on the throttle to build and maintain the consist. Employed by third party wireless throttles which cannot access the throttle bus protocols and commands in the same manner a native throttle can.

- Advanced Consisting; Decoder Based: All locomotives share a common address assigned by the command station. The consist address is stored in the multifunction decoder's CV19[1]. The command station will set CV19 using Ops Mode[5] for all the locomotives in the lash-up. It is in the Primary Address space, beginning at 127. The command station will decrement that address as new consists are created. The original Primary and Extended Addresses are not altered (CV 1, 17/18). The command station can economise on bandwidth by sending one packet for all the units in the consist. It may be possible to address individual units for the purpose of sending a function command. The lash-up is portable from layout to layout, since the information needed is stored onboard the locomotives.

- If a locomotive will not respond to its address, it may have been part of a consist that was not cleared. Setting CV19[1] to zero will clear the consist address.

- Unified Consisting: The consisting method is a mixture of Basic and Advanced Consisting. Only Digitrax and NCE support these under the term Nested Consisting.

- Nested Consist: A consist within a larger consist.

Comparison of NMRA Consisting Terminology with Manufacturer Terms

| Alternate Terminology for Basic and Advanced Consisting | ||

|---|---|---|

| DCCWiki.com | ||

| Manufacturer | Basic Consisting | Advanced Consisting |

| NCE | Old Style[6] | Advanced |

| Digitrax | Basic/UniVersal | Advanced |

| Lenz | Double Traction (DTR) | Multiple Traction (MTR) |

| Easy DCC | Standard | Advanced |

| Zimo | Double Header | |

| MRC | Universal[7] | Advanced |

Consisting with Digital Command Control

There are three ways of creating a consist with Digital Command Control. Each consisting method has its advantages and disadvantages. Not all methods are supported by all systems - check your documentation if you aren't sure what you can do with your equipment!

- Basic / Decoder Based: All multifunction decoders in the consist have the same Primary or Extended address.

- Advanced: All multifunction decoders in the consist have the consist address stored in CV 19, while retaining their Primary or Extended Address.

- Universal / Command Station: The command station manages the individual locomotives in the consist.[8]

Another method which is beginning to appear is Throttle Based Consisting. This relies on the throttle creating and managing the consist, instead of the command station. Usually found on third party wireless throttles.

Basic Consisting, Decoder Based

The simplest method of creating a consist. Program all the locomotives in the consist with the same address. This can be a Primary or Extended address. The locomotives must all be facing the same direction, as direction of travel is determined by their orientation. If it is planned to operate locomotives as a permanent consist, such as an A-B-A set, the NDOT must be set accordingly.

The Basic Consist's advantage is using one address only in the command station. The command station will see all locomotives with the same address as a single locomotive, and they respond to commands in unison, including functions.

If the consists were created with a Primary address (1-127), there may be issues operating as a consist on another layout. There will be conflicts if the primary address is also used by another locomotive which is not part of the consist.

- An analog (non-decoder equipped) locomotive cannot be part of a Basic Consist.

- Decoder Based Consisting is easy to use and understand: All multifunction decoders in the consist have the same address.

- The operator cannot control individual locomotive functions such as the horn, bell, and lighting, as all the decoders will act on the command.

Creating a Decoder Based Consist

Once the locomotives for the consist are chosen and tuned to match each other, place all the selected locomotives individually on your programming track and set the desired address for the consist. All locomotives will now have the same address. Doing each locomotive individually avoids overloading the Program Track output, which may cause erratic results.

- Remember, if the consist is separated, all the locomotives will still respond to that address until reprogrammed to new addresses.

Advanced Consisting

Also known as Decoder Assisted Consisting, Advanced Consisting uses a temporary secondary address (in CV 19) to group locomotives together without changing the Primary or Extended Address. The locomotives keep track of the consisting information. If the locomotives are taken to another layout the consist will still function, as it is stored onboard the locomotives.

Advanced Consisting reflects that it is more advanced than Basic Consisting, as the Primary or Extended addresses are unaltered, with individual control of each locomotive in the consist possible. Advanced Consisting is considered a better choice than relying on the command station to create and manage consists.

The consist uses a single address in the command station. It is limited to a Primary Address. There may be address conflicts when operating as a consist on another layout.[9] When creating a consist manually, avoid an address already in use by another locomotive which is not part of the consist. Removing a locomotive from the consist without clearing the consist address in CV19[1] will result in an orphan locomotive which responds to the consist address.[10]

Advanced Consisting is done by using ops mode programming to set configuration variable 19 to the consist address and direction of movement. This also requires reprogramming the decoder to change the consist, but some systems do this transparently to the user. Some decoders will allow the operator to specify which functions respond to commands addressed at the consist address. Creating and breaking the consist are handled by the command station using specific commands sent to the decoders.

The command station sees the consist as a single locomotive:

- The consist address is stored onboard the multifunction decoder

- The consist address is a Primary Address (see below)

- Some command stations may include the ability to easily create an Advanced Consist within their software

- The consist is portable because of this

- The operator can control any locomotive's function operation from its specific address

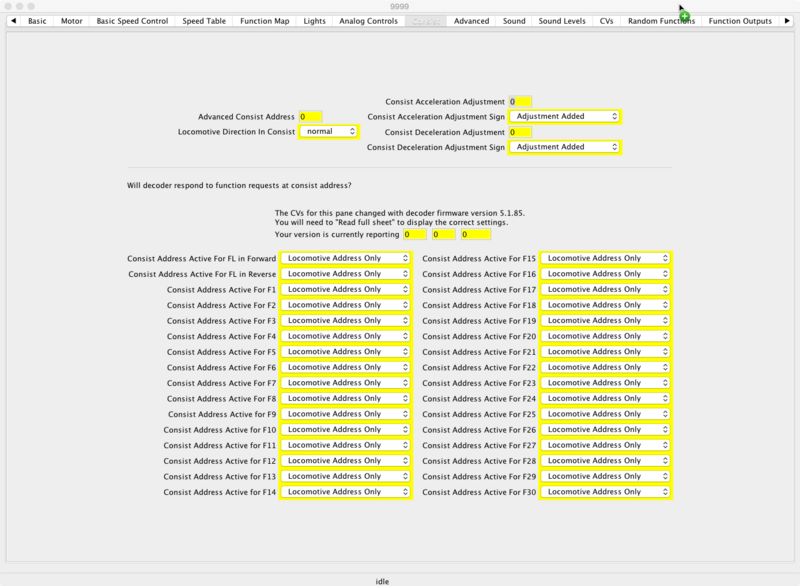

- CV 21 (F1–F8) and 22 (FL, F9–F12) can set the functions available on any locomotive in the consist

- An analog locomotive cannot be part of an advanced consist

- Advanced Consists operate in 28 speed step mode

Additional Features

- Main article: Mutiple Unit Consisting/Consist Configuration Variables

CVs 21 through 24 are Optional, and may not be included in a multifunction decoder's parameter set.

While part of an Advanced Consist, a locomotive cannot respond to function commands sent to the consist address[11]. There are two optional CVs, 21 and 22, which can enhance consist operations in this mode. Acceleration and deceleration also can be further adjusted using CVs 23 and 24.[12]

For control of functions, CV21 and 22 are used. CV 21 is responsible for F1 to F8, CV 22 controls lighting effects (FL) and functions F9-F12. Acceleration (CV 23) and Deceleration (CV 24) can be fine-tuned by adding their value to those in CVs 3 and 4. CV23 and 24 can contain positive or negative values. These CVs must be programmed prior to the locomotive being using as part of a consist. Most DCC systems do not do this automatically, the user is required to manually program these CVs.

Since CV 23 and 24 are optional, their method of implementation can vary. The NMRA DCC Standard does not require them to be active during consisting. Some multifunction decoders may activate CV 23 and 24 in an Advanced Consist, others may not. They may need to be activated by setting another CV. In other cases, the decoder may ignore the sign of the values in CV 23 and 24, only adding a positive value to CVs 3 and 4.

Address Space Conflicts

Advanced Consisting uses an address in the Primary Address space. If Primary Addresses are in use for Multifunction Decoders, it is possible to have a consist address sharing the same address as a vehicle on the layout. In this situation the locomotive with that address and the consist will move in concert. It will be necessary to re-assign the consist to an address which does not create a conflict. See the manuals for the DCC system for details.

EPF Consisting

Extended Packet Format is another term for Advanced Consisting, where consist information is stored in each decoder. Locomotives can be added or removed in any orientation. All locomotives in the consist must be equipped with decoders supporting this feature, which allows a consist that is "transportable" from one DCC layout to another, but ensure the locos are on the track in the same order and orientation when they were programmed to avoid unexpected results. Most decoders today should be compatible with the Extended Packet Format.

Notes about CV19

CV 19 is used to consist the locomotives by writing a common address for the consist.[1]

CV 19 can be altered in one of three ways:

- Using Service Mode (programming track), either manually or by the use of a computer

- Manually using Operations Mode

- By the Command Station

The command station can use specific Consist Control commands to configure the decoder. See Digital Packet article for more detail.

If a locomotive was part of an advanced consist, clearing CV19 (by writing a value of zero to it) removes it from the consist.[13]

Decoder Assisted Consisting

See Advanced Consisting above.

- Main article: Multiple Unit Consisting/Decoder-Assisted Consisting has additional details on this consisting method.

Universal / Command Station Consisting

All the bookkeeping chores for the consist are performed by the command station. With this method, no changes to the programming of the multifunction decoders are made. Each locomotive in the consist is a separate entity in the command station, so the size of the consist is limited to the capacity of the command station. Analog locomotives may be a part of one consist - all analog locomotives on the track will respond to the same commands, so one can't run them in different consists.

Consists may be stacked, making up consists within consists. Locomotive functions can still be individually controlled without affecting other locomotives in the consist. The command station sees the consist as individual locomotives, sending each locomotive its own speed and direction commands.

- The lead locomotive's address is also known as the Top Address.

- The functions are only acted on by the top address, or lead locomotive.

- Functions on the other locomotives can be controlled directly from their address

- Since the command station does the housekeeping for the consist, there will be memory or software-imposed limits on the number of consists.

Other Implementations of Universal Consisting

- The following systems allow any address can be used, with the exception of Address 00.

- Lenz

- Double Header (DTR)

- Two locomotive limit

- Double Header (DTR)

- NCE

- Old Style

- Eight locomotive maximum

- Old Style

- EasyDCC

- Standard Consist

- Eight locomotive maximum

- Standard Consist

Digitrax UniVersal Consisting

- See Command Station Consisting above.

- This is a proprietary method of consisting.

Digitrax calls their implementation of command station consisting UniVersal Consisting (Yes, with a capital "V" in the middle).

- When UniVersal Consisting is in use the characters "cn" will appear in the address line on the throttle display

With UniVersal Consisting, the consist responds to commands sent to the Top Locomotive (Address). The top locomotive does not have to be the lead engine, nor does it even have to exist. The consist is managed by the command station. An analog locomotive can be included in the consist. UniVersal Consisting Allows:

- Any address to be used, including Address 00.

- Number of consists is limited by the number of slots.

Digitrax systems such as the Chief also have Unified consisting, which automatically selects the type of consisting to use. To include Advanced Consisting the FX status must be set. If not set, UniVersal consisting will be used, the most common method used by Digitrax users.

Summary

| Summary of Consisting Methods | ||

|---|---|---|

| DCCWiki.com | ||

| Consist Type | Decoder Based | Notes |

| Basic | Yes | All multifunction decoders have the same address |

| Advanced | Consist information stored in CV19 | |

| Universal / Command Station | No | Managed by Command station |

| UniVersal | Managed by Command station, Digitrax Only | |

Throttle Based Consisting

Throttle Based Consisting is a new method often found with third party wireless throttles. These throttles will connect to the throttle network using a WiFi connection.

In this instance, Command Station Consisting such as Digitrax's UniVersal Consists are handled within the wireless throttle. This method was chosen due to the proprietary nature of LocoNet. Design of the throttle's software allows usage on multiple throttle networks without the requirement of throttle configuration changes when connected to a new network. In addition, it permits the throttle's software designers to side step multiple protocols and network languages to make this feature work, avoiding any licencing issues surrounding proprietary technologies.

DecoderPro

DecoderPro offers a number of options when setting up a consist, depending on the multifunction decoder installed. The image below is for an ESU LokSound 5 multifunction decoder

Best Use of Each Consisting Method

- Basic Consisting is best used when command station slots or limited memory capabilities are at a premium (because of either command station limitations or large numbers of trains to be run) or locomotives are always run together (such as A-B-B-A sets for long passenger trains). Since you are programming the primary address for these locomotives, it is best done on a separate programming track rather than on the layout where you might accidentally reprogram ALL the locomotives on the layout.

- Advanced Consisting can be used in the same circumstances as Basic Consisting, but can be done on the main layout using operations mode programming since you select the individual locomotive before programming it. The consist address is limited to short addresses, so this might be an undesirable restriction if you want to use the train number as the address. Some DCC systems have ways of controlling the Advanced Consist using a long address.

- Universal or Command Station Consisting is the most convenient method which requires the most system resources. This can be an issue if your command station has limited memory available or a large number of consists are in use.

- Digitrax Example: An entry level Digitrax Zephyr command station is limited to 10 slots and for operators wishing to run four trains with three locomotives each, that's a total of 12 slots using this method - it's not going to work. You'll have to use one of the other consisting methods for at least one of the trains. Also see Dispatch[14].

- NCE Example: NCE command stations do not have slots and as such does not require the user to be aware of them. There is no requirement to dispatch a locomotive. NCE's Entry Level system is limited to two engines per consist with a maximum system limit of 12 unique engine addresses in use simultaneously. Therefore, the NCE entry level system can run up to a maximum of six consists of two locomotives each. The only way it could run four trains with three locomotive each would be by using Advanced Consisting.

- Consisting methods can be used in a "mix and match" style:

- Digitrax Entry Level Example: If you have three locomotives running together as a basic consist (one slot), three running together as an advanced consist (one slot), and four running together in a command station consist (four slots), you can create another advanced consist bringing all 10 locomotives together, and it will use no more than six slots.

- NCE Entry Level Example: It could run the same setup as Digitrax, the only exception being that a given engine cannot be used in more than one consist at the same time. So, you cannot do the last step of create another advanced consist using the previous locomotives. However, you could run 10 more locomotives in an advanced consist if those 10 locomotives were not part of any consist.

- An analog locomotive can be part of command station consist if it is supported by the DCC system, but it cannot be part of a basic or advanced consist which rely on the installed decoder to determine the consist.

Digitrax UniVersal Command Station Consisting

- Main article: Multiple Unit Consisting/Digitrax Advanced Consisting

The greatest advantage of the command station consists as implemented by Digitrax is its flexibility.

It is not difficult to add (or delete) locomotives or groups of locomotives to a consist, making assembly of long trains with multiple mid-train helpers effortless (common on N-Trak layouts) or to add/remove helpers to get a long train up a steep grade. It is important to remember though that while it is still using one slot per locomotive with this method – and the most capable system from Digitrax has 120[15][16] slots available, command station consisting is not suitable to use on large layouts where you are expecting more than 20 or more operators at a time.

The TOP locomotive is the address controlled by the righthand throttle on an Advanced Throttle (DT200/300/400/500/602). When this address is Dispatched, the entire consist is Dispatched.

UniVersal Consisting is a mixture of Command Station and Advanced Consisting methods. The command station will determine the best method, and if the multifunction decoder's status allows, write the consist address to CV19. If not, it will use an internal database to link the consist's decoder addresses together.

NCE Consisting

The advantage of Advanced Consisting as implemented by NCE is its flexibility. NCE utilizes a hybrid of Advanced and Command Station consisting, where the consist address is in the multifunction decoder's CV19[1], and the command station maintains a table of aliases for managing the consists. It is very straightforward to add and delete locomotives or groups of locomotives to a consist (nesting), making it effortless to assemble long trains with multiple mid-train helpers or adding helpers to assist a long train on a steep grade.

Depending on the NCE system chosen, you can control from 16 to 127 unique advanced consists. There is no limitation on the number of engines within a given advanced consist. The NCE command station has the ability to control a given consist using the lead locomotive's address regardless if it is a long or short address.

Specifically, if the locomotive has a long address, that long address is used to control the consist (an Alias). In other words, use the engine number like you would normally if the engine was not part of a consist. Unique to NCE is the ability to dynamically redefine the leading locomotive consist without turning the engines around. Select the last engine of the existing consist and instantly it becomes the lead engine of the same consist. Included in this change is both train direction and function control (headlight and sounds). The advantage becomes obvious when running a train down a stub branch which has no turning facilities. It goes forward down the stub branch line to the end and leaves going forward in the opposite direction. This action follows the prototype, where the crew would relocate to the front engine.

A nested consist is constructed using Command Station consisting to manage multiple Advanced Consists and/or a mix of individual locomotives and an advanced consist. A maximum of four pre-defined advanced consists may be combined into a temporary single consist. Hence, you can temporarily add a helper consist to a train with a lead consist, climb the grade using one throttle, subsequently break the nest consist into their original individual consists. Afterwards, the helper consist goes down the hill to await the next train.

To construct an Nested Consist:

- Use Advanced Consist to create the leading set

- Use Advance Consist for the helpers

- Use Old Style consisting to link the Lead and Helper sets together as one unit

To cut off the helpers:

- Delete the Old-Style consist,

- Send the lead and helper set (Advanced Consists) on their separate ways

NCE has a consist browser which allows management of all of the advanced consists by:

- Viewing the locomotives in a specific advanced consist. and

- Editing consists

NCE Consisting Notes

- Main article: Multiple Unit Consisting/NCE Consisting Notes

Videos

There are several videos available through the Videos page:

Consisting with SoundTraxx Decoders: More on consisting methods.

NMRAx

The DCC Guy

A Quick Video about Consisting

Soundtraxx prepared a short and simple video demonstrating various types of consists:

Notes

Nested Consist

Nested Consist describes two consists which have been merged into one, such as helper/pusher locomotives, allowing control from a single throttle. When they are no longer needed, the consist can be split into its component parts, such as the helpers disconnecting from the train and returning to the bottom of the grade to await the next train. Your manuals should explain how this is done.

Creating a Nested Consist

Here is the basic process. The exact process may differ by manufacturer.

- Create an Advanced Consist with the leading set of locomotives

- Create an Advanced Consist with the trailing set of locomotives

- Use Universal/Command Station Consisting to merge the two consists

Operate as a set normally would be operated. When the time comes to break up the consist, simply delete the consist in the command station. The leading and trailing consists can now be operated independently.

Unified Consist is another term for this method of consisting.

Speed Matching

- Main article: Speed Matching Locomotives

An important task before creating a consist is to ensure that all locomotives within a consist run the same speed. If you don't do this, some locos will run significantly faster than others. This will result in tug-of-war between locos, or a push/pull between the locos. This is hard on the couplers, as well as the locomotives themselves. This can also lead to derailments.

The goal: With the same throttle setting, each locomotive travels at the same speed (or the same distance at the same time). Think of method as distance/time matching rather than speed matching.

- Also read the article on Back-EMF for more details.

Read your documentation for the decoder as well, as it may have advice on speed matching, plus CVs needed. CV29 enables the speed table, if available.

See Also

- CV Worksheet

- Speed Matching Locomotives

- Back EMF

- Decoder-Assisted Consisting - Use the decoder to create the consist versus the command station.

- Consisting Tsunami decoders with Lenz DCC system - Specific information for controlling functions on Soundtraxx Tsumani sound decoders from Lenz DCC systems.

- Dispatching: A method to clear slots, as well as work around short and long address issues.

- Issues with NCE and Consisting

- ABCs of Consisting, an NMRAx clinic by Bruce Petrarca

- Consisting with SoundTraxx Decoders: More on consisting methods.

- LokSound5 Advanced Consisting with the LokProgrammer

- Soundtraxx has a Youtube presence with videos explaining how to use various features.

- Gotchas! at the JMRI website regarding speed matching.

- The Complete Guide to Consisting

- Digitrax

- Consisting Primer at NCE's Zendesk

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 CV19 is Optional as per the NMRA DCC Standard S-9.2.2

- ↑ If a locomotive will not respond to its assigned address, verify CV19 does not have a value greater than zero. This has caused many modellers a lot of trouble when troubleshooting an unresponsive locomotive.

- ↑ CV19, Bit 7 set to one: Reverse direction

- ↑ Basic Consisting can use any valid primary or extended address.

- ↑ Ops Mode allows the command station to send specific commands to a specific decoder address.

- ↑ NCE may also use the term Forced in their manuals.

- ↑ Universal Consisting may be called Old Style in some MRC manuals

- ↑ Universal Consisting is sometimes called the Brute Force or Old Way of consisting.

- ↑ Correct orientation and sequence are important, as the direction is part of the address in CV19, and CVs 21 and 22 determine functions available to that locomotive.

- ↑ This is a common problem, where a locomotive will not respond to its address. If it won't respond after being removed from an advanced consist, the problem is that the consist address (CV19) wasn't cleared when the command station broke up the consist.

- ↑ Only the Top Address will respond to a function command.

- ↑ CVs 23 and 24 are optional as are 21 and 22. Their inclusion is not required by the NMRA Standard.

- ↑ If the address in CV19 is greater than 127, the locomotive is running in reverse.

- ↑ The DCS51 and DCS52 versions of the Zephyr increase the available slots to 22.

- ↑ The DCS240+ offers an additional 280 expanded slots accessible by the DT402 R2, DT500, and DT602 throttles only.

- ↑ JMRI does not support the Expanded Slots.