Digitrax Hints and Tips

Summary: A collection of hints and tips to help use and troubleshoot your Digitrax DCC system

| Digitrax Pages... |

|

Local Home Page |

Command Stations

Recommended Power Supply Voltage

DCS100/150

- Maximum Voltage: 20VAC, 28VDC.

- Minimum Voltage: 12VAC, 12VDC.

- Current: 5A

DCS200

Recommended voltages are similar, with a maximum of 22VAC. An eight amp power supply is recommended.

Zephyr Xtra / Zephyr Express

Only use the power supply which was packed with the unit at the factory. The Zephyr will warn if voltage is too low or high for proper operation, and will not allow track power to turn on if too high to protect decoders.

- AC Voltages are RMS, for 50 and 60 Hz.

Command Station Option Settings

- Main article: Digitrax Hints/DCS Option Switches

- Main article: Digitrax Hints/DCS210+ Option Switches

Many command stations from Digitrax have options which can be changed. Your preferences are stored in volatile memory, whose contents are lost when power is removed. This memory is maintained by a coin cell (such as one used in a watch) in the command station. As the cell ages, its ability to maintain the memory declines.[1] At some point the memory will reset to the command station's defaults. If the command station starts behaving badly, replacing this cell is a good place to start. Modern semiconductors use very little current, so this cell can last for years.

Status Editing

Source [2]

A Digitrax DCC System has additional memory built into the command station. A portion of the user programmable memory is called Status. When an address is entered for the first time, the command station stores information about this address in a memory location called a Slot. When viewing or editing the Status, it is actually some of the data in the slots that you are actually looking at.

Typical Digitrax systems allow 22 to 120 slots, meaning 22 to 120 Loco's decoder addresses and/or throttles. This is in part why Digitrax offers such a balanced system. Newer command stations such as the DCS240 offer up to 400 slots, in combination with the correct throttle.

Programming means programming the multifunction decoder’s memory using a programming track. Status or Status Editing, refers to programming the command station's internal memory, not the decoder.

Selecting a new or existing decoder address on a throttle shows the status of this decoder. This is shown in one of two ways, depending if Primary or Extended addressing is used.

With a Primary address the throttle will show AD:xy, AD = Decoder Address, and xy = Status Code. With extended addresses it will show St:xy on a rotating display. This Status will either be the system default, or the status previously entered into the command station.

Editing Multifunction Decoder Status

This process was often required in the early days of DCC, telling the command station that this decoder does not understand the 28/128 speed step mode. To get a new decoder working, a status edit was needed to switch the command station's default behaviour to 14 Step Mode for this decoder. This was often encountered with early Lenz, Marklin and Arnold decoders.

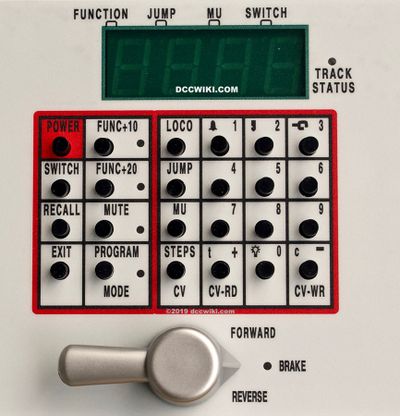

DT100 Throttle

Select a locomotive on a DT100 throttle by pressing the SEL/SET button. Once the desired address is shown on the display, press FUNC before pressing the SEL/SET button again. This key press sequence enters the Status Edit mode. Use either the throttle knob(s) or the Up/Down buttons to change the status. Once the desired status is set, pressing SEL/SET saves the value to the command station.

DT4xx Series

Press the EDIT key to begin Status Editing

What Do the Actual Status Codes Mean?

- Main article: Digitrax Hints/Status Codes

Slots

- Main article: Digitrax Hints/Slot Management

If you see a SLOT=MAX message (the Zephyr[3] and Zephyr Xtra[3] use FuLL), you need to clear the slots. Please see the article on Slots for more information, and the related article on Dispatching.

My Train Keeps Stopping

If you have a train that will, for no obvious reason, suddenly come to a stop, and if you adjust the throttle, it resumes its journey, the most likely cause is that two throttles are set to the same address.[4]

There are two slots assigned to that locomotive's address. The one slot is set to speed zero. At some point the command station will refresh the slots. It reads the slot which is set to zero speed and sends a packet to your locomotive telling it to stop.

JMRI can help by using the slot monitor to clear all unused slots, as well as using it to release a specific slot.

See the article about dispatching for more details.

Additional Cooling for DCS200 and DB150

Sometimes it's necessary to add cooling to command stations and boosters when running in certain environments, such as outdoors in hot weather, or in an enclosure. Here is a process to add a 12v fan to a DCS200 and DB150. Pictures to come soon.

Warning: This may void your warranty.

- Remove the cover case

- Use a fret saw to cut a U shape into the box

- File off the rough edges

- Bolt the fan to the heat sink with three bolts.

- The fan blows into the box's interior and up the heat sink.

- Fan power is taken off half of the bridge rectifier output, the PCB contacts of which are easily spotted once the box is removed.

- To allow free air movement, a couple of rubber grommets are added to the rubber feet.

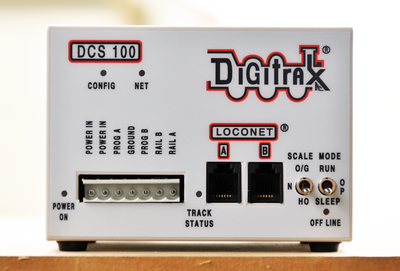

DCS 100 Command Station

Resetting a DCS100

If things are a little strange, or after a long and large operating system, this procedure will clear out and reset the DCS100 to factory settings.

- Set the Mode Switch to the OP position

- Disconnect both LocoNet cables, plug in a DT400 throttle.

- Press SWCH, 39', CLOC 'c' (Same process as throwing a turnout with a throttle.) The display should show Sw 039=c.

- Set the MODE switch to RUN. This is very important, do not skip.

- Set the MODE to the OP position.

- Press SWCH 5 c. The display should indicate that switch is now closed, the same applies to the following steps.

- Press SWCH 15 c.

- Press SWCH 20 c.

- Press SWCH 44 c.

- Return the MODE switch to the RUN position.

- Disconnect the throttle and reconnect the LocoNet cables.

The DCS100 has been reset, and it ready for operation.

Procedure adapted from a document prepared by Northern NJ N-Trak

DCS100 LED Indicators

Net Indicator

- Solid Red: LocoNet OK

- On, blinks Off: Valid LocoNet Message Received

- Off: Short circuit on LocoNet

- Blinking: DCS100 is in configuration mode

Off Line Indicator

The indicator can mean two things:

- No Track Status

- Overheat Condition: Once the DCS100 cools, it will return to normal operation. It shuts down when the temperature reaches a point between 45º and 50ºC.

These are normal conditions.

Track Status

- OFF means no track power, or the DCS100 might be turned off

- Orange: Normal DCC operation with no zero stretching

- Green or Red: Zero Stretching is in use.

CONFIG

Indicates the operating mode of the DCS100, Slow blinking is normal. This tells you that the OpSwitch 5 is set correctly.

Eight blinks every 4 seconds indicates that OpSwitch 5 should be closed. Normal operation is possible.

If it is mainly off, then OpSwitch 1 is not correctly set. It should be "thrown".

DB150 Diagnostics

DB150 Power LED

A green LED indicates the DB150 is on. It also indicates status.

- Solid: Normal operation as a command station.

- Flashing

Faults

If a fault has occurred, the power LED will turn on for 4 seconds, then off 4 seconds, followed by a number of blinks before beginning the cycle again.

- One blink indicates a short

- Two blinks mean OVERTEMP

- Three blinks indicate loss of packets, a LocoNet problem.

Audible Alerts

If you get twenty beeps, your LocoNet may be overloaded. Disconnect the LocoNet and this should stop. The solution is to ensure that LocoNet is getting power from an alternative source so as to not load down the command station.

For a list of alerts, see

- Main article: Digitrax Hints/Digitrax Audible Alerts

Changing a Command Station to Booster Only Mode

Digitrax publishes through their Knowledge Base a number of articles regarding setting their command stations to Booster Mode.

It is not possible to have two command stations on the layout.

- Note: If a command station is being used as a booster suddenly changes back to the default (command station) mode, this is often caused by the coin cell which maintains the memory in the command station. When it cannot supply enough energy to maintain the settings (option switches) you have stored in the command station, the device will reset to its defaults.

- https://www.digitrax.com/tsd/KB371/dcs100-converting-to-a-booster

- https://www.digitrax.com/tsd/KB179/zephyr-qa-dcs50-as-a-booster

- https://www.digitrax.com/tsd/KB1018/dcs100200-booster

- https://www.digitrax.com/tsd/KB580/zephyr-xtra-making-dcs51-or-dsc50-a-boosterthrottl

- https://www.digitrax.com/tsd/KB1036/dcs240-indicator-lights

Digtrax Zephyr / Zephyr Xtra / Zephyr Express

For keypad issues see Throttle Repairs

Messages

- Main article: Digitrax Hints/Zephyr Messages

The DCS50 and DCS51 display error messages on the LED display:

Walking L

Loss of Carrier: If the display shows a "walking L," the Zephyr is in booster mode, and there is no active command station. If the LocoNet cable is disconnected in booster mode this error will appear as well. Either power up the command station or check the LocoNet wiring. If needed, verify the LocoNet wiring with the LT1 tester.

If the Zephyr is the command station, it will need to be corrected. OpSwitch 2 should be Thrown (factory setting) to put the Zephyr into command station mode. OpSw 39 can also be used to completely reset the Zephyr to factory defaults.

Walking "c"

Current Overload

The walking c indicates the booster is overloaded. Reduce the load by running fewer locomotives. A booster can be added to increase the current capacity of your DCC system.

Walking o

There is a short circuit on the power bus which must be corrected. Look for something on the track or a derailed vehicle.

Walking "H"

This message indicates an over voltage condition exists on the power input. The power supply has gone bad, or an inappropriate AC power supply is being used.

The DCS51 is designed to be operated from a 12V battery, or a PS314 power supply (included). Using an AC power supply will result in this error message.

- If an AC power supply such as the PS315 or PS515 is used the track power cannot be turned on to protect your equipment on the layout.

DCS52 Zephyr Xpress Error Messages

As the DCS52 has an LCD alphanumeric display, it can display more meaningful troubleshooting information. Error messages will be displaying on the Scrolling Help Text line.

- Local Booster Track Fault: Short Circuit Shutdown due to overload. The DCS52 will beep three times and flash the track power indicator

- High Input DC voltage: Excessive voltage for the power supply, which should not exceed 16.9V. The PS314 is the power supply which should be used with the DCS52.

- LOW Input DC voltage: Should the input voltage drop below 9.5VDC, the unit will display this error and beep continuously.

FuLL or SLOT MAX

If the word FuLL (or SLOT MAX on the Express) appears on the display, the slots are full and need to be cleared before additional locomotives can be addressed. If this message appears during operations, you can clear unneeded locomotives by pressing LOCO, entering the address, then pressing the Exit key.

See the page on Slots for more details.

Digitrax Knowledge Base Articles

- https://www.digitrax.com/tsd/KB1022/zephyr-xtra-dcs51-messages

- https://www.digitrax.com/tsd/KB819/zephyr-customizing-operation-with-option-switches

Throttle

- Main article: Digitrax Hints/Throttle Troubleshooting

Digitrax Throttle Guide (HoTrak.ca)

Radio or Infrared Throttles Sluggish

When operating either kind of wireless throttles on a Digitrax layout, sometimes you'll notice a slight delay. The Digitrax wireless throttles only send a speed data packet when you stop moving the throttle knob. So, if you continuously decrease the throttle to zero, the only command sent is ZERO SPEED when you hit bottom. If you play with the throttle knob all the time, there won't be a command sent until you quit fooling around!

Here are some ways to improve throttle response.

- Check that Address 00 is not in use, or has not been left in the system at a non-zero speed. Because of the way analog operation on a DCC layout works, use of an analog locomotive can significantly slow response to throttle commands, with the problem getting worse as the analog locomotive runs faster. Many clubs have banned the use of analog locomotives during operations sessions for this reason.

- Slow Down! Turn the throttle knob about one click every ½ to 1 second. This is slow enough for the throttle to send the command between clicks.

- Try using the [+] and [-] buttons instead of the throttle knobs for making speed changes. Again, space out the commands.

- Add another UR90 (Infrared) or UR91 (IR and Radio) receiver to your layout. A few people have argued that lower signal strength further away from the receiver, or too many throttles talking to a single UR91 may contribute to the issue. People who have added a second receiver have noted some performance improvement on bigger and/or busier layouts. This is obviously a more expensive solution - try borrowing one first if you can to see if it improves things!

Range is not usually an issue with Digitrax throttles. Anecdotal user experience gives an IR range of over 30 feet, with some ability to bounce off reflective surfaces, and radio ranges over 200 feet under good conditions - on other floors, outside the house, or even across the street!

Erratic Operation

During an operating session with multiple trains in motion and multiple operators, trains stopping and starting for no reason can be caused by address conflicts. As the LocoNet is polled, a locomotive address which occupies more than one slot will cause problems. If the throttle is set to zero, the train will stop until the other throttle using that address is polled.

Dispatching locomotives properly will probably eliminate the problem. Clearing all slots after an operating session by dispatching all the locomotives should also help.

Radio Throttle Issues

- Main article: Simplex,_Duplex_and_Infrared#Interference_Issues

Basic Information about Wireless Throttles

From an email on the Digitrax Mailing List

- Simplex throttles use frequencies in the 915 MHz band.

- Duplex throttle signals are in the 2.4 GHz (or 2400 MHz) band.

Bluetooth and WiFi devices also operate in the 2.4 GHz band, so they can and will interfere with Duplex operations. The amplitude of the Bluetooth signal is such that it will drown out your duplex throttle; if standing close to a UR92 duplex transceiver you may find it overwhelms that device too – a phenomenon called receiver-capture — the strongest signal captures the receiver and blocks other signals.

- Solutions

- Advise everyone to turn off Bluetooth devices, or just disable the Bluetooth option. Wireless routers can auto-negotiate whatever channel it wants in the 2.4GHz band, which is also used by the UR92, at up to ten times the power of the Digitrax throttle and transceiver. Again, receiver-capture will kill Digitrax Duplex communications.

- Set router for B/G protocols, a fixed channel (Such as #1) and minimum bandwidth in the 2.4GHz band, set the UR92 to use channels further away from the router's channel.

- UR91 and UR92s should also have their own power supplies, don't rely on the Loconet cables. Sufficient power means better operation.

Powering Throttles

As with any electronic device, a throttle requires power to operate. This power is not to be confused with the signals received and sent by the throttle. A throttle takes its power in the following sequence when plugged into the following jacks:

- a UP3/5 panel that is connected to a 12 - 15 volt DC power supply (sometimes referred to as a wallwart).

- a UP3/5 panel that is connected to the track power.

- If the UP3/5 panel is not connected to a 12 - 15 volt DC power supply or to the track power, the UP3/5 panel takes its power to operate from the LocoNet (Pins 1 & 6 or the white and blue wires in the LocoNet cable).

- An RJ12 6-wire telephone jack takes its power from the LocoNet (Pins 1 & 6 or the white and blue wires in the LocoNet cable.

The only time a throttle takes power from the battery to operate is when it is unplugged and you are using the throttle to send signals to a UR90 infra-red receiver or to a UR91 radio receiver. When unplugged the battery keeps the display lit but does nothing with respect to the signals that have been generated by the throttle or the command station.

- Note: On a system that includes throttles without batteries it is especially important to use powered UP3/5 panels or something similar to prevent the RailSync (Pins 1 & 6) voltage from dropping too low. Low RailSync voltage can cause premature battery discharge and/or throttle problems. If the RailSync voltage drops below 9 volts, then battery powered throttles will revert to internal battery power even when plugged into a LocoNet jack. If it drops below about 7.5 volts, the LocoNet becomes unstable and you will have loss of control problems.

Cannot Control Turnouts

First, you cannot control turnouts unless they are equipped with a switch machine driven by a stationary decoder.

If the first conditions are met, yet control of turnouts from the throttle doesn't work, there are two reasons. Both are related to the Bushby Bit. Reason one is, the layout is controlled by a dispatcher, and you must request that a turnout be thrown. The dispatcher will do that using a computer interfaced to the layout using LocoNet.

The other reason is that the Bushby Bit was accidentally set. It is OpSw27 in a Digitrax command station. The Op Switch must be reset to enable the operator to throw turnouts from an advanced throttle.

Throttle Repairs

Replacement Potentiometer for the UT4 Throttle

If the potentiometer (or pot) on the UT4 throttle is not working or broken, it can be replaced with a new Alps Rotary Potentiometer RK09D113000K.

See Replacement Potentiometer for Digitrax UT4 Throttle for details.

Replacement Encoder for DT100

If the rotary encoder fails, it can be replaced by a Bourns Rotary Encoder Mechanical 3315, part number 3315Y-001-006L. Most electronics suppliers will have this part.

Replacement Encoder for DT40x

If the rotary encoder fails, it can be replaced by a Bourns Rotary Encoder Mechanical 24PPR part number PEC12R-4220F-S0024-ND. Most electronics suppliers will have this part. The Bourns PEC11R-4215F-S0024 is similar, but with a metal shaft.

There are other types which lack the detent, which is the -4020F- variant.

The knobs can also be replaced with larger versions. The originals used by Digitrax have a tight press fit on the shaft.

Capacitor Plague

The Capacitor Plague was a problem between 1999 to 2007, where electrolytic capacitors from certain suppliers failed at an unusually high rate.

DT300 and DT400 series throttles can suffer from this issue.

The solution is to replace the surface mounted electrolytics with new ones. The originals are 4.7uF, 25V which can be replaced with a similar or larger value. Someone skilled in soldering should have few issues replacing the two capacitors.

DT300 Symptoms

If the capacitors have failed a DT300 will often alternate the display with a voltage reading then a series of random numbers.

Keypad Issues

This is an advanced topic.

In time with use the keypad may wear out. Some buttons may function perfectly, others are erratic in their performance. This condition has probably been seen with other devices, such as remote controls, with rubber keypads.

It is possible to recondition the keypad. Unfortunately, Digitrax does not sell replacements. Note that it will take effort to disassemble the throttle to remove the rubber key moulding.

The contacts on the underside of the key pad can be reconditioned using products design for that purpose, available from most large electronics distributors such as Digikey. One product is the Chemtronics CW2605. Be sure to follow all the instructions and warnings as it is a professional grade product.

Rechargeable Batteries

Going through batteries on a regular basis is no fun, so here's a list of batteries that should work in all Digitrax throttles.

The throttle uses a nine volt battery for power.

- http://www.mahaenergy.com/store/viewItem.asp?idProduct=273 (+ see notes below)

- 9.6 volts, fits all throttles, need NiMH charger.

You'll need a NiMH charger. Maha also makes great chargers for all NiMH batters (different voltages/cells).

- http://www.mahaenergy.com/store/viewItem.asp?idProduct=364 1

- Compatible with 8.4V and 9.6V 9V batteries.

- Charges 4 batteries at a time.

- http://www.mahaenergy.com/store/viewItem.asp?idProduct=274 1

- Compatible with 7.2V, 8.4V, and 9.6V Rechargeable 9V Batteries.

- Charges 10 batteries at a time.

1 Manufacturer's website for reference. Although they sell their own products, you can usually buy their products cheaper from other online retailers.

Another Comparison of 9V Batteries

DT 400 Battery Compartment Dimensions:

- Available space in DT400 Battery Compartment: 1.065" wide, 0.720" deep,1.932" long (27.1 X 18.3 X 49.1mm)

- Total length of battery, including positive & negative clips

Typical 9V Battery Specifications

| Comparison of 9V Battery Dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|

| Width | Height | Length | Total Length | |||||

| Inch | mm | Inch | mm | Inch | mm | Inch | mm | |

| Duracell 9V/HR9V/DC1604/NiMH/8.4V/150mAh | 1.033 | 26.24 | 0.673 | 17.1 | 1.789 | 45.4 | 1.897 | 48.2 |

| Duracell 9V MX1604 6LR61 Alkaline | 1.020 | 25.91 | 0.656 | 16.7 | 1.740 | 44.2 | 1.894 | 48.1 |

| Eveready 1222 6F22 9V Alkaline | 1.009 | 25.63 | 0.673 | 17.1 | 1.777 | 45.1 | 1.899 | 48.2 |

| Energizer 522 6LR61 6AM6 9V Alkaline | 1.000 | 25.40 | 0.645 | 16.4 | 1.908 | 48.5 | 1.894 | 48.1 |

| Personnelle 9V MX1604 6LR61 Alkaline | 1.034 | 26.26 | 0.667 | 16.9 | 1.774 | 45.1 | 1.896 | 48.2 |

Typical 9V Battery Specifications

- 17.5 X 12.95 X 46.4mm

- Height including terminals: 48.5mm.

- Typical volume is 211 cubic millimetres

- Shelf life is 5 years at 21ºC.

- ANSI-1604A, IEC-6LR61

Table Notes:

- Length excludes the terminals (body only)

- Total Length includes the terminals.

Powering UP or UR panels

To power a UP or UR panel, and any throttles attached to it, Digitrax now recommends their PS14 power supply, which is a 14Vdc 300mA wallwart (power brick). As noted in the UP manuals, the PS14 can power 10 UP or UR panels. This works out to 30mA per panel, or simply 300(mA)/10(units)=30(mA each).

This is consistent with the fact a LocoNet device such as a throttle can draw up to 15mA from the rail-syncs whenever the rail-sync voltage is greater than 7V. The UP5 simply provides Loconet throttle connections, no Rail Sync signal just positive voltage, on the front and to the side jack. The UP5 uses Diodes to select/steer where power is drawn from. When no track or Rail-Sync power is available the UP5 will use the external power to power the Rail Sync to power the Throttles and to save batteries.

Power Usage of Throttles and Panels

| Device | Power Usage |

|---|---|

| UR90 receiver (IR only) |

up to 30 mA |

| UR91 receiver (Radio & IR) | |

| UP3 panel (Obsolete) |

0 mA† |

| UP5 panels | 0 mA† |

| Throttles | 15mA |

† Does not include LED status light. According to the technical data on the UP3/UP5 panels, the panel does not get voltage from the Loconet to light the LED status light - that power is drawn only from the rail connection, if any. But will use the track power if higher than the Rail-Sync or the external DC if applied.

UP-5 Power Plug Size

Unfortunately, the Digitrax manual doesn't state this, but the plug size for the UP-5 is a 2.1 by 5.0mm coaxial power connector.

Radio Panels

UR92 Troubleshooting

This process requires an interface between LocoNet and a computer.

JMRI features a Duplex Group Configuration feature under the LocoNet menu.

The window that opens when selecting this feature offers both Group Identity and Channel Scan.

The Channel Scan will scan all the channels available, graphically displaying signal strength. This will allow you to select a channel for your duplex throttles which has the best performance and least interference.

The DigiGroupSet from Digitrax can also perform this task.

These tools are very useful in optimizing the performance of your duplex throttle network by determining which channels to avoid.

Digitrax PR3/PR4

Digitrax offers an interface to LocoNet, currently it is the PR4.

The PR3 has been superseded by the PR4. A previous device, the PR2, was a serial device.

Digitrax has instructions for installing software the PR3/PR4, for various flavours of Mac OS and MSWindows. Make sure your software is up to date if you start having issues, especially after a software upgrade. An old version may work well for years until an upgrade, even a minor one, to the operating system breaks something. Digtrax has updated the firmware to work with 64-bit operating systems, if yours is a 32-bit OS, no need to upgrade the firmware.

- There are instructions for windows10 on the Digitrax website.

- The Mac OS uses JMRI to access the PR3/PR4. To use them you need to have Java and JMRI installed on your Mac.

PR3/PR4 Issues

Resetting CV128

The PR3 and PR4, when in stand-alone mode, can reset CV128. This can cause frustration when after programming a Digitrax decoder the vehicle will not move.

Digitrax Sound Decoders use CV128 to toggle the motor on and off. This allows the user to test the sound settings without the motor's current draw overloading the PR3/PR4. To do this it sets CV128 to 0.

This is not a problem with Digitrax sound decoders, but other sound decoders use CV128 for other purposes. Setting it to zero can cause problems.

PR4 IPL Issues

Older products can have issues when being updated with a PR4. The PR4 needs to have Option Switch 14 closed. This will enable the Legacy IPL mode.

This issue mostly affects the update of DT402 throttles. Other legacy devices can have similar issues during an update.

PR4 Status Lights

- USB, when solid blue, indicates MS100/Loconet Interface mode.

- If the device is connected to the USB bus, it will be lit.

- If the device is in SoundLoader/Decoder Programming mode, it will be flashing. This happens whenever the Soundloader program is active on the computer.

- The red OPS light will be lit and flashing red/green when the PR4 is in Option Mode. The only time this occurs is during a reset, or when setting Option Switches

- The green LED is not important. It is there for factory use.

Option Switches

There are two option switches available.

Option Switch 14

Some legacy products have slower processors which cannot keep pace with the faster PR4 data rates. This issue often occurs with IPL updating DT402 series throttles.

To enable Legacy IPL mode on the PR4 ensure you have the latest PR4 Firmware installed and set OpSw 14 = c (closed) by following the instructions which came with the PR4. The device must be powered and connected to the USB bus when doing this. To return to normal PR4 mode, repeat the process to set OpSw 14 = t (thrown).

Option Switch 40

This option switch resets the PR4 to its defaults.

My Locomotive Will Not Move, but has Sound

Digitrax Sound Decoders

Sometimes the PR3/PR4 will alter a CV during programming a Digitrax multifunction decoder so the sound effects can be tested. It writes a value to CV128 to disable the motor. If the motor will not respond on the layout, write a value of 1 to CV128.

Saving the Throttle Battery Between Sessions

To keep your nine-volt battery in a DT100, 200, 300, 400, or UT4 throttle from discharging between operating sessions, open the battery case, remove the battery, and roll it (so that the polarity of the battery is reversed from that shown on the case). Reversing the polarity will not hurt the battery or throttle - people have been doing this since the DT100.

Do not swap ends with the battery! This will short the battery out on the spring at that side of the case. It won't hurt the throttle electronically, but the battery will get 'very warm. It doesn't do much for the life of the battery, either.

Also see DT402 Manual, P21

Using LocoNet Power to Maintain Battery

This arrangement allows you to turn off your command station and booster when it's not operating, and leave a simple wall wart plugged in. For this, you need to have a power supply such as the Digitrax PS14 installed and connected to a UP panel. This will supply power for up to 10 UP panels and connected throttles as long as the power supply is active. Of course, if you have the PS12 or PS14 plugged into a switched outlet that goes off when you power down your layout, you'll have 20 dead batteries in your throttles when you come back... so be sure of your power!

Alternatives to Battery Rolling

I don't have this information on me, and I can't find where I first saw it. But, about nine months ago I saw a webpage that describes how to use a Digitrax PS12 power supply and a multi-female RJ12 receptacle device to build a portable, or at least something you can mount in the garage, that allows you to plug in multiple throttles into. This acts as a battery saving device for wherever you store your throttles. For the life of me, i can't find this website. It was such a simple circuit to build too. I'm posting this here in case anyone knows of it and wants to replace this text with either a link or information on how to build it. Thanks. TazzyTazzy 12:41, 17 January 2006 (EST)

- I tried a google search - is this it? Seems to be obsolete, given the UP panels...Joe Ellis 18:51, 19 January 2006 (EST)

- Joe - thanks for looking, but that's not it. It's a standalone device. So, say if you have your layout in the garden, or at a club, and you bring your throttle home (or inside), you simply plug it into a standalone device in the garage (or wherever) and it acts like a battery saver. There were no relays. Just a power supply and a box that had multiple female to receive the throttle jack plugs. Once I understand the LocoNet wiring, I could come up with my own layout/design for this magical box, but why recreate the wheel? :-) TazzyTazzy 20:00, 19 January 2006 (EST)

- I have been searching for such a device recently and came across this page. I have since found a reference on Digitrax's site for a DT200 keep-alive, and I think it would work for any/all of their throttles -- same basic principle. From my prior experience on electronics, I would recommend each RJ12 jack have its own separate resistor but it should be safe to wire multiple jacks in parallel off one power supply. Digitrax Application Note (Scroll to "DT200 Keep Alive" at the end of the page)

- Follow-up: I have received a response from Digitrax support confirming that that circuit should work. The support representative said, "I know nothing about that very old battery saver circuit but if okay for the DT200 it will work for all other throttles. I would stick with 12 volts dc power to it."

Battery Saver

- By Don Crano

This a little circuit that Don Crano built with AJ's help. It is designed to turn the entire LocoNet into a battery saver for the Digitrax Big Boy System. It could be modified to work with the Chief if one desires. When installed on the LocoNet it will supply power to it, and put all throttles in to IDLE mode automatically. Today there are the LA-2 and UPx panels, as well as other products to keep the power on the LocoNet.

The standby power supply is 500mA 12 VDC wall wart. The input supply can actually be any transformer that powers up and down with the system. The power supply for the booster is ideal for this. The relay is a 4P2T relay with a coil voltage and type to match the supply used. I use 18 VAC 6 amp transformers to power my boosters, and a 24vac relay works fine.

How It Works

When the LocoNet is powered up, basically nothing, all is normal. When the system is powered down and the relay drops out things change a little. The Orange wire of the LA-1 is moved to the + side of the standby power. The Red & Green LocoNet power wires are connected to the Black & Yellow LocoNet ground wires. This causes all throttles on the LocoNet to go IDLE. This might be all you need and, in that case, a 2P2T relay will work. But you will also notice that it removes the Blue & White wires from the Booster. The original DB100s did not have the bleed resistor on the caps that the newer ones do. Without these, the standby power would charge these caps and cause the booster to sometimes boot up in reverse polarity or other strange things. So I cured this by having the LocoNet Blue & White data wires disconnect from the booster.

- This may not be needed anymore, as long as there are devices keeping your LocoNet bus energized.

DigiIPL

DigiIPL and DigiIPLII are Digitrax specific firmware updating tools. The Integrated Program Loader is used to update the firmware in various devices, such as throttles, Utility Panels, and Command Stations.

The DigiIPL software has some serious shortcomings. The most significant is it doesn't really report back version numbers. Making it difficult to determine which version is installed on the device. It also presents challenges when trying to update the firmware, as well as making it very difficult to revert back to a previous version.

The device itself makes the decision to accept or reject a firmware update, which requires no intervention from the DigiIPL software. There is no feedback mechanism, meaning that the firmware may be accepted or rejected without warning, as well as no indication of sucess or failure.

If you do update the firmware in a Digitrax device, affix a label to the device indicating which firmware revision you last installed.

For more information, visit the Hostlers Inn

Third Party Devices

Many devices from other makers will work with Digitrax equipment. Some are LocoNet Certified, others do not have LocoNet capabilities for control and programming.

Digitrax Programming Conventions

Digitrax uses the Thrown and Closed nomenclature when programming their system's configuration switches. Other manufacturers do not use the same terminology.

| Manufacturer | Thrown | Closed |

|---|---|---|

| Bachman | Diverging | Straight |

| MRC | Off | On |

| Lenz | − | + |

| NCE | ||

| Normal | Reverse | |

| On | Off | |

| 1 | 2 |

Power Management Devices

PSX from Tony's Train Exchange / DCC Specialties

Read the instructions thoroughly, as there are a number of settings required. Programming can be very tedious if you don't read the instructions first because of the command station transmitting addresses upon startup.

One is the "low power system" setting, needed for the Zephyr and Zephyr Xtra.

They may not work correctly if Zero Stretching is in use.

Consisting and NCE DCC Systems

The Digitrax default consisting method is Command Station Consisting. Digitrax calls their method UniVersal consisting. All consist information is stored in slots in the command station's memory. The command station splits the consist address into individual commands to each address in the consist.

NCE uses a hybrid version of Advanced Consisting which they call Intelligent Consisting.

When consists are operated on an NCE system, the consist must be broken up before removing the locomotives from the layout. Their consisting methods are not 100% compatible with Digitrax consisting.

Should this happen, the locomotive will appear to operate normally, without responding to throttle inputs. To correct this issue, write a value of zero (0) to CV19. This will erase the NCE short address which was written into the CV as part of the consisting process.

References

- ↑ In this application the cell will last for years. Adding a note indicating the replacement date is a good idea.

- ↑ Adapted from a webpage by the late Don Crano (site no longer available)

- ↑ 3.0 3.1 The Zephyr has only ten slots, where the Xtra and Express have twenty available.

- ↑ This is called a Ghost Throttle.